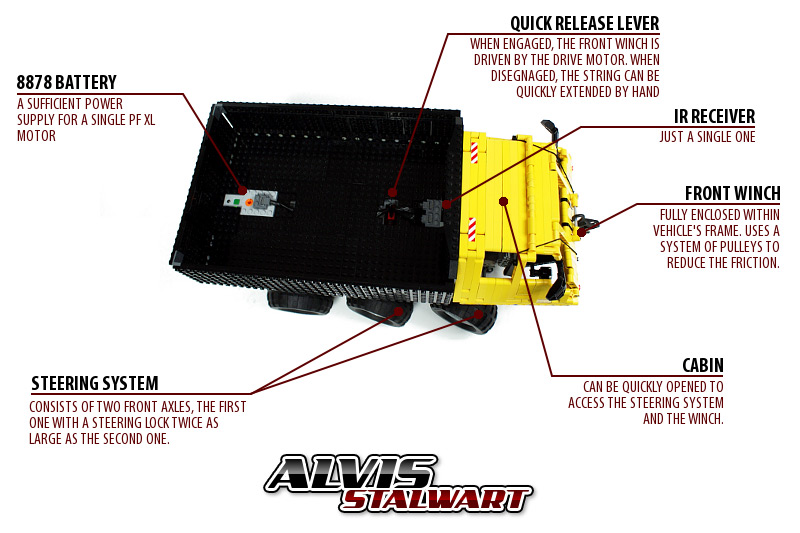

Alvis Stalwart

My fourth Trial Truck vehicle. Features 6×6 drive, two axles with different steering lock, full independent suspension and front winch with a quick release lever. The first vehicle powered by the Lego 8878 battery in Polish Truck Trial.

Datasheet:

Completion date: 05/09/2009

Power: electric (Power Functions)

Dimensions: length 53 studs / width 27 studs / height 24 studs

Weight: 1.875 kg

Suspension: full independent

Motors: 1x PF Medium, 1x PF XL

My another attempt to create a successful Truck Trial vehicle. Having my previous experiences with Unimog U900 and Star 266 in mind, I focused on a vehicle that would be small, light, low and simple. I have chosen to model the Alvis Stalwart truck because it was one of the shortest off-road vehicles with three axles. I liked the idea of having six wheels so close to each other, because if offered good traction and good weight distribution.

The chassis was complex but compact, built almost exclusively with liftarms. It consisted of two steered axles both of which were copies of the module I have used in the front axle of my earlier Hellbender model. The third axle was not steered. The intervals between all three axles were identical, which meant that the second axle was supposed to have 50% of the first axle’s steering lock.

The problem was that two aforementioned modules were located in ‘mirrored’ positions in order to simplify the drivetrain. Therefore the steering driveshaft had to have its direction of rotation reverted between the modules. It was achieved with a simple setup of small bevel gears, but it also created a significant backlash. Initially there was 16-teeth gear in the first axle’s rack & pinion mechanism, and an 8-teeth gear in the second axle’s one. In theory it provided the desired difference in steering locks of two axles, but in practice that difference was heavily degraded by the backlash. I have solved it eventually replacing the 16-teeth gear in the front axle with a 12-teeth one. Coupled with the backlash, it created just about the perfect steering lock difference.

The drivetrain was somewhat complex, with two separate driveshafts for the third axle and for the two first ones. The model was driven by a single PF XL motor located just above the third axle, and the 8878 battery was located at the very rear end of the chassis – together with the PF XL motor it counterbalanced the weight of the cabin. I expected the front winch to be a very important part of the vehicle – it was driven by the drive motor through a driving ring with a quick release lever. When the lever was engaged, the winch was driven accordingly to the direction of vehicle’s movement. When the lever was disengaged, the winch was disconnected from the motor and the string could be quickly extended by hand. There was a number of pulleys used inside the chassis to reduce the friction of the string, and the entire winch was enclosed within model’s frame. The winch proved so powerful and robust that when forced to stop, the string split before there was any mechanical damage.

The model was a bit heavier than expected, but it had a very good weight distribution and the suspension worked flawlessly with its weight. It was also quite manoeuvrable and very, very stable. I expected the low ground clearance to be a problem, but it was helped by the bottom of vehicle which was covered by a protective layer of smooth liftarms, so that the model could slide over obstacles to some extent. The main problem of the vehicle was failing drivetrain plus non-lockable differentials. A lot of slip situations occured, and the drivetrain would snap when a really high torque was needed. It could have been helped by the use of the winch, but it worked way below the vehicle’s travelling speed, which proved fatal – the winch was simply to slow to take the load off the wheels. It would work much better if the release mechanism disengaged wheels from the drivetrain as the winch was engaged.

The model has lost its first and only race, but in some aspects it performed much better than any of my previous trucks – it remained stable at all times, it did not suffer any damage despite the use of many delicate parts such as CV joints or universal joints, and it did not formally malfunction – it simply suffered from the drivetrain being unable to handle high torque. It was also acclaimed by other Truck Trial builders for capturing the original vehicle’s look, which kind of surprised me. Moreover, the experimental use of the 8878 battery turned out to be a success – the model’s performance was not degraded, while its weight with a traditional battery box would exceed 2 kilograms.

Photos:

Video:

Media reference:

Mao de ABS (Spanish only)

@Jonathan

No, they’re smaller.

@sariel

What size wheels do you use and are they the same as the BMR-2

Many thanks,

Jonathan

Ok,thanks for your help.

@Paul

It had an independent suspension.

Very nice truck! You did a great representing it in Lego form. But,do you know if the Stalwart had independent suspension in real life or something as,such as pendular suspension?

thank you your a big help i find steering hard for me:example tatra 6×6 double steering is very hard any tips on strong yet compact steering i hope im not a bother to you

@David

Depends on many things: for example on the angle and on where you attach the shock absorber.

i was wondering for stiff shocks does a truck need alot of wieght

@blarson

Quote: “Initially there was 16-teeth gear in the first axle’s rack & pinion mechanism, and an 8-teeth gear in the second axle’s one. In theory it provided the desired difference in steering locks of two axles, but in practice that difference was heavily degraded by the backlash. I have solved it eventually replacing the 16-teeth gear in the front axle with a 12-teeth one.”

It’s in the text up there. You could just read it.

thanks but i mean how do you have the first axle steer lets say 45 degrees and the second alxe like 35 degrees

@blarson

Ever heard of transmission?

How do you get the moter to both the 1st and 2nd axle?

@geraell

NO. You’re making me regret making instructions for anything.

Plz sariel can u make instructions for alvis???

Plz plz plz plz plz plz plz!!!!!!!!!!!!!!!!!

@Emil Bech

Why are you asking me about things that you can read in the description above? Problems with reading?

Hi Sariel

Does the truck stear on the 1. and 3. axel? And drive on all of them?

Best regards Emil

@Sariel

oh, I’m sorry!

@Maxwell

BRICKLINK. I have written it everywhere, on this website, and in all my videos, and I assume you can read, can’t you?

I’m from Germany and im 16 years old and i wonder where you got all those parts for the steering system. (:

If it slips inside a frame then perhaps the gear’s teeth are damaged. I’ve been testing brand new differentials inside a frame, driven by PF XL motor, and they didn’t slip even once.

Oo0oh, sorry to bother you again.. but i have tried that, but it still slips. Do you recommend a washer to increase tight contact between the gears?

Put it inside a liftarm frame or inside a bracing.

yo sariel, im having problems with my 8297 differential because the gear keeps slpping against the differential and the teeth on the differential gets blunt and damaged.. how do i fix this because i noticed you 2 are using the same diffs. and you have no problem with it.

oops! that was a reply to matthew for taking up the whole page. Not you. 🙂

youre taking up the whole page you idiot now shut up! 🙂

@NeuroMimetis

Some people stuff things inside the tire, like small tires or rubber bands. You can try gluing if you’re really desperate. For me, the best solution is to have vehicle with at least 6 wheels – it’s practically impossible to see the rim slipping in all of them.

@peter

I’ve heard already about people complaining because the lego wheel was slipping into the tire.

It sounds like water and soap, after driying, can solve the problem.

your website is excellent and has got me into building truck trial. however recently i have had an issue with the wheel rim slipping inside the tire. im using the offroader wheels (94.8 x 44r) plz help!!!

sorry

@matthew

No, you should probably check it with Lego and stop producing a dozen questions per day.

Do you know how to get a job in lego?

@matthew

I don’t know yet.

Do you think the Tatra T815 is going to be better than the Alvis?

Will it have any cool features?

@matthew

As far as I remember, not.

Did you ever use the winch last year?

@matthew

We were allowed last year, but currently it’s forbidden. Not my decision, I don’t know more about it.

In truck trial are you allowed to use the winch on the Alvis e.g for pulling up hills or over obstacles

@matthew

Someone else does.

Do you organize the races in Poland,or does someone else?

@matthew

No.

Is there a certain age limit to participate in truck trial?

@Andre

That’s odd, because I’ve never noticed the new differentials snapping when placed inside these frames.

If you refer to the frames that come with the 8258 crane truck, yes. I noticed the problem first when making the crane truck motorized. For now I have resorted to removing the differentials, which works fine with a rock crawling truck.

@Andre

Have you tried putting the differentials into the new open liftarm frames?

Your website is a real inspiration! I have built my own truck but now I have run into trouble. Even though I use the same differentials as you do, I have trouble with gears slipping (resulting in damaged differentials). I have tried many different gear combinations, but still the truck can not drive over obstacles, the differential seeming to not be strong enough. Can you give me advice to overcome this please?

thanks. time to buy the 8297 set.

@Joe

I don’t make instructions on a principle. All the steering pieces come from the 8297 set.

would u ever be able to do instructions? its just ive never been able to make a good chassi. and if not can i have the part numbers for the steering peices? all mine seem to start off good but then a big problem comes up like the steering wont steer or somthing stupid like that!

@samogitian

Regular or absent. There’s no space for locking differentials, and there is absolutely no space for torsens.

I always wondered what kind of center differentials are used in Lego Truck Trials. Are they absent (solid axles), locking, open or perhaps torsen? 🙂

@ Arnau

When I built my indep. front suspension, I tried to make a wheelhub (is that what it’s called? 🙂 ) that supports the axle along a 2 studs long part, not just one stud long. If this sounds messy, I can send ya pics!

@RjbsNXT

It’s pretty much the same, except the one you shown is worse because it uses old towball couplings and hence is wider. A proper scale is required in the Polish Truck Trial races, and in fact my Alvis should have been a bit narrower.

@max7695

How about using this chassis?

http://www.mocpages.com/image_zoom.php?mocid=131646&id=/user_images/17884/12463744273

i have end i made a few but they didn’t work so i hope you could help me

@max7695

Then you need parts from the 8297 set.

i saw those but i want indipendent suspension for offroad

@max7695

I did. Check the Ideas category, will you?

but cant you make a instruction how to make an other front axel with suspension ant drive axle

@max7695

No. For a number of reasons: e.g. it was extremely complex, and now with the new open liftarm frames it could be largely simplified.

could jou make a instruction how to make a front axle with suspension and front wheel drive

@LEGO4×4

I have used 8297’s suspension components, but not its steering system, because as you probably know very well, 8297’s steered axle is not driven.

Did you use the same steering mechanism as set #8297? Kinda Looks like it

@Sariel

OK thanks!

@Yoraish

7:1 if memory serves me well.

what was it’s gear ratio?

@tomthegom

That depends on the type of obstacles you are going to face. From my experience the independent suspension performs better, but the pendular one is often more robust and easier to build.

is independent or pendular suspension better for a tt?

@Willis dee

Yes, the rules of Polish Truck Trial require everyone to build an accurate model of a real vehicle. But this is just a local solution. As far as I know guys in Czech run their own Truck Trial races with no such rule.

When you make these trial trucks, do they have to look like a real existing truck? I like to think that im good at making chasis and all the guts, but when it comes to making it look like something I have no clue.

@mythbror

I thought 8466 comes with complete steering & drive modules. I have used 8297 components, but I had to develop my own module. I have taken some photos from under the chassis, these may help you. I have no better way of explaining the construction, as it was really very complex.

I started building an Alvis Stalwart before you finished and I have almost completed it. I was inspired by legostalwart’s model on YouTube. I read an Alvis Stalwart has one differential that connects the left a right wheel modules. The wheel modules contain three wheels that are joined with bevel gears mostly.

@Sariel I would like to know how you assembled your steering modules–I am using steering parts from 8466 and adding steering was difficult.

@bonzo

Thank you for that information 🙂

if the car had alot of slip situation then just remove the diffs. i had a lot of good experience with no diffs in trail truck

@Sariel

The wires on the front of the stally are the winch cable and towing cable stowed on the front for use

I dont know how you do it but your a genius at legoss

@tomthegom

I don’t know, I’m not the organizer. The truck had independent suspension, which is very uncommon for Trial Trucks and makes it stand out.

why arent you having more tt’s this year

the truck is great but it looks a bit too springy why was that?

@legoMasteR

No, I won’t.

pleas, make instructions for alvis starwalt

@arnau

That may be caused by backlash in links, this is typical for 8880. Perhaps try buying new links and axle towballs.

@Sariel

What I mean is that they aren’t always parallel when going straight

@arnau

No wonder wheels are not parallel – the 8880 set uses Ackermann steering geometry 🙂

@Sariel the same steering as in lego 8880

@arnau

I have no idea what your steering system looks like.

in every model I build I find the problem that the steering wheels(if they have suspension) aren’t parallel to each other at all times. how can I fix this?

@bobsurankle

The real vehicle has strings on cabin, I guess these are the mooring lines as the vehicle is amphibious.

Very good, (as usual), its a shame about the drivetrain problems, a question: what is the string around the cabin for?

bob’

@Jeffrey D

I’m sorry, it is too late. I just finished taking the Alvis apart yesterday, I needed parts for the excavator. Next year, when I prepare another truck (a new version of Alvis perhaps) I’ll try to show details of entire chassis.

Is it too late to get us some pictures of your winch mechanism? I’d love to see it =p

@Julian

No, unfortunately I have no idea what the Truck Trial community looks like in USA. There are some countries in Europe that I know have active communities, like Czech Republic, France or the Netherlands, but I haven’t heard from any US-based community.

Do you know of any American trial truck races i would love to try my hand at one al be it i am not nearly as good of a builder as you

fajny pomysł:)

WOW!!!!!!!!!!!!! great

@Isaac

Sure I will, except next race is scheduled for 2010. I’ll probably try with a Hummer H1 or with a rebuilt Alvis.

@Sariel

Well at least you tried in the trial. Good luck next time if you play next time.

again a very nice vehicle. I would love to see some more pictures of the internal mechanics

Good job! I like in particular the cab and in general the front part of the vehicle design. Just the caisson looks a little bit too large maybe.

@Isaac

No, I lost. Too many problems with the drivetrain. If I could fix that one thing, this truck would have a serious chances in the race.

@Julian

No, I have no interest in LPE. The traditional PF motors meet all my needs, and there are already guys who make probably the best LPEs that can be built 🙂

Very nice one day i hope i could built as great as you can. Also a question will you be planning a LPE(lego pneumatic engine)?

Good job! Did you win? your truck is kinda fast for a trial truck, too. Great way of using the pf rechargable battery box for the trial, because it’s lightweight.