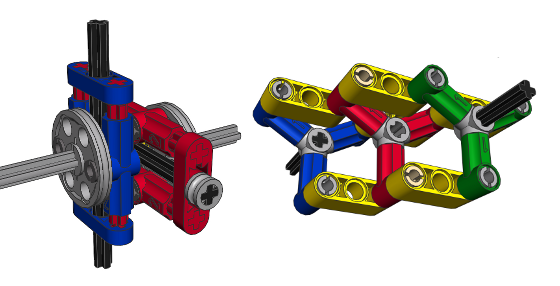

Oldham coupling and Schmidt coupling

Two interesting mechanical solutions for transmission systems.

The Oldham coupling and Schmidt coupling are two various mechanical solutions for transmitting drive between two parallel axles that are not aligned in line. That makes them alternative to universal joints, which are long, and to gear wheels, which only fit in specific spacings and affect power/speed ratio if not meshed at 1:1 ratio.

The Oldham coupling consists of two identical rotors, each connected to one axle, and a sliding element between them. The coupling shown here can handle input/output displacement of 1 vertical and 1 horizontal stud. It can be expanded to allow larger displacement by using longer axle in its sliding element, but that increases its diameter drastically. In short, the Oldham coupling is short and maintains 1:1 ration, but is complex, fragile and has large diameter.

The Schmidt coupling consists of three discs or triangles connected with links – three links per disc/triangle, giving six links total. The first and last discs/triangles are connected to the axles while the middle one simply hangs in mid-air. The unique property of this coupling is that it can work while its input and output are moving relatively to each other. That makes it an interesting solution for transferring drive to the moving elements of your construction. The Schmidt coupling is also extremely robust and can handle high torque while generating minimum backlash. Its main disadvantage is the length – in this case 5 studs – and the fact that it’s built around a rare LEGO piece.

@larrytmaxx

It’s shorter than u-joints and it does what gears can’t do. I suggest you watch the video again, because it seems you might have not understand it.

that looks larger than how big the gears are and longer than the u-joints together

@Sariel

My mistake. You’re right, the instructions are correct. Sorry about that. I double-checked before posting and still mis-read them.

@Mickey Mouse

Yes, you need 4. Hence the “4x”, while “2” denotes length of the axle.

In the instructions for the Oldham coupling, in the top-right hand panel it says you need 2x 2-length shafts when you actually need 4

@Jerkerhead

That depends on a space.

Wouldn’t gears of something fit into a small space better than this

I really enjoyed this Lego versions of coupling! both are mechanisms that love to see in real machines, and your versions are just perfect.

One more time I’ve shared this on mi blog: technicdelicatessen.blogspot 😉

@Hector

It is not made of Legos, is it?

The IBM 3890 High Speed document sorter uses Schmidt couplers. The machine process documents at a speed of 1100 docs/min.

I think that these mechanisms are more magic than practical…I mean they are fragile extremely long and last but not least , visualize them under pressure ….I suggest that you build a temporary chassis to test these or make art with them: big contraptions with many of these connected to each other. 🙂

@neamerjell

The Oldham doesn’t handle high speeds too well. The Schmidt does, provided you make sure it has proper space to work, that means it’s not squeezed lengthwise.

These are really neat. I would guess that the Oldham coupling would be impractical for most uses due to the friction and tendency to bind. At first glance, the Schmidt coupling seems to address both of these issues. Did you test either of these at high speeds? Did they bind up and self destruct as many of my poorly designed gear trains do? I can’t begin to count how many things I’ve tried to build and scrapped due to axle alignment issues.

@Alessandro

The instructions were put together in LPub from a model created with the MLCad. It’s the standard that I’ve learnt to use while working on my book and which I’m using in it. I hope it will look good when printed.

Good technical exercise. I agree with TLT803, I can’t figure out any practical application. Good instructions page. May I kindly ask you which software did you use to make them ?

Thank you for posting these! They’re rely cool but I can’t think of a application for them just yet…

Wow, I really like your schmidt coupling!