Compact pendular steered suspension

Simple steered and driven pendular suspension. Very compact and strong, needs no rare parts. Step-by-step instruction provided.

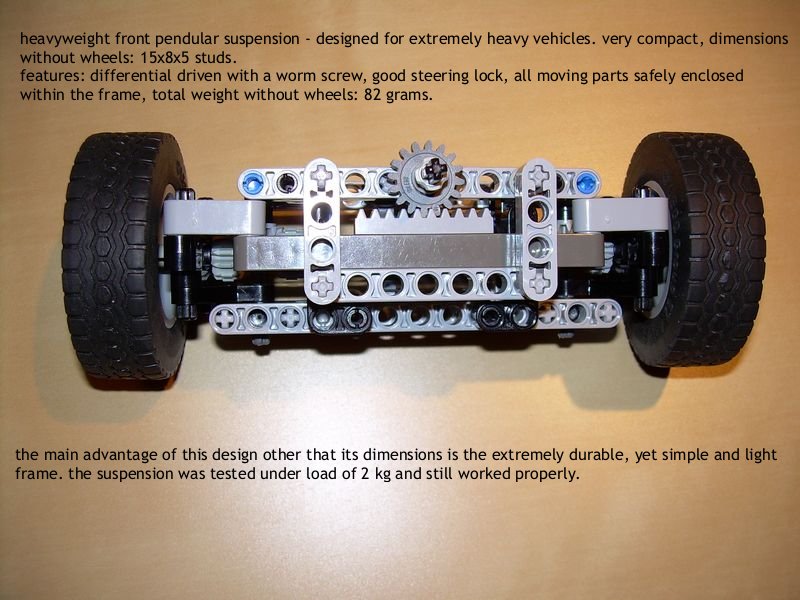

One of my most popular and useful ideas. It’s a simple driven and steered pendular suspension, built without use of any rare parts like universal joints etc. It requires mainly liftarms and bevel gears. The full parts list can be seen here. The entire module’s dimensions are 15x8x5 studs plus wheels. The weight is 82 grams, and it has been successfully tested under 2 kilograms of load. All the moving parts are enclosed in liftarm frame. You can find a complete step-by-step instruction on the photos below.

@Fin

maybe your thinking of the newer, 3 stud wide ones, this is thinner, yet it is 4 studs long

@Fin

No, they don’t.

Dont the teeth on th diff rub the casing

@Jon Håvard

This design comes from before the 3-studs wide differential. I suggest to check my newer ideas.

Could you make one with the 3-studs diff? Guess you have other plans… 😛 no offence

@freakybuilders

No, I lost this file somewhere.

Could you please send me the LDraw File to freakybuilders@web.de?

Thanks

@Salih

You can build one from the Lego 8880 set.

Can you post instructions for steered, independent suspension with drive or tell me a website where i can find one please?

@Alexr

You should add shock absorbers for stability. There are plenty of ways to do so.

@Sariel

so you what you are saying is that you don’t need springs.

but wont it just tip over?

@Bartek

Nie.

Szkoda, jestem Twoim fanem i często wzoruje się na Twoich projektach 😀

Miałeś może kiedyś problem z silnikiem PF XL taki iż kabelki nie łączyły??

@Bartek

1. Bo 90% odwiedzających to osoby spoza Polski. A po polsku moje konstrukcje opisuję na Lugpolu.

2. Nie.

Witaj, dlaczego tu jest wszystko po angielsku skoro to jest polska strona??

Chciałem się spytać czy robisz instrukcje do swoich projektów ????

@Dan

No, I don’t, sorry.

Hey Sariel, would you still have the ldraw file from this, do you still have it kicking around, I’m working on changing the way it is driven and it takes way too long by physical bricks. So maybe you could send me the file? Anyways great job on this system, I’m going to be using it for my physics project involving the purpose of differential gears, it was the best one I’ve found.

Hi I have 14 years

thank you very much, it works very well and Land Rover this Tanvi done.

guillem greetings from spain

@puredeath

Try this: http://sariel.pl/2010/07/4-speed-compact-linear-gearbox/

is there a way to make a even numbered wide steering or an even numbered wide gearbox [transmision] and there is another way to make a version of this with less parts or larger and im working on trying to build a car with my mindstorm nxt useing the 3 mindstorm motors, the “brain”, and the mindstorm ir transmiter and receiver. My remote does not have speed control and ur return 2center disign is not strong enough to move the moters onec the get withen 5 degress or so of center, and i dont have the parts to build and grear box greater than 4 speeds and i have a working version of ur 4 speed manual gear box. I have to have 2 motors suplling the powers to the wheels because the nxt “brain” is so heavy that it strains all the chasies i have made with transmisions and some of my first direct drive cars do u have and ideas i could build and i have 1 differintral no shocks

thx

e-mail me at: Narutokiba11@yahoo.com

and if anyone has any ideas u can e-mail me 2

Yes, exactly.

Hey, how does the 16 tooth gear with clutch act as a pinion? since it does not have a cross-axle hole in it, is it turned by yet another gear from above?

I continue to be awe struck by the quality coming from this website. If we, in the LEGO community had the ability I would see that once a year we would vote, worldwide, on the best, in a number of categories, and present them, not only with the international recognition they so richly deserve, and a nice trophy, and we would ask LEGO to donate some LEGO parts that the winners want so ban that they drool when they simply think about them. I am just sick and sadden, here in a nursing home and no money, when I come here, first thing, and see all of the new creations. Believe it, or not, but I see things here that ARE NOT SOLD IN THE USA.

Now, I first want to award Paul with the top recognition for keeping this website growing, and looking so professional. When I place this site beside websites that are for corporations with millions to spend, their sites “suck”, some of my 6th grade students have done better.

Next, I wish to congratulate Paul for the development in his design work…it comes out with each and every model that he has created. For 25+ years I was known as the “LEGO Maniac” which came from LEGO-USA for developing my schools and using LEGO as the manipulative elements for developing concepts they could carry throughout life, and serve them well. One of my students, through our hacking access into ‘milnet’ and hacking into MIT, he became friends with Rodney Brooks (Head of AI and Robotics). Once Chris graduated from High School Rodney invited him to work his way through MIT by developing the AI and ‘brain’ for LEGO. What few people realize is that we were a full 5 years ahead of LEGO with the motorized LEGO vehicle carrying a “Smart Brick” inside. This was the first step for LEGO into the world of Robotics and it came from my school. He then went to Stanford-JPL and is now on the team that has developed the “cross-over” vehicle, seen on TV and soon to start roaming the highways across the USA. I have had, from 1983 to 19998, over 278,256 students go through my 2,878 schools in all states. When I became deathly ill I had to withdraw my Founder/Headmaster positions, and when I was in the hospital I suffered 56 strokes (I survived all of them without so much a mark that would reveal to the casual visitor, that there had been, or remains, some issues that keep me here. My mind is fresh and unharmed, if I had lost my ability to think and develop, I would fall into a depression that I would fear that I may do something to myself…which won’t happen as Hospice (for people dying with a very short period of time…I am now 6..6 years in Hospice, they kicked me out of their care…Why? I didn’t die when all of my doctors said I wouldn’t lase 6 weeks after the major operation. See, I’m a tough Irishman. While I was out sick, my mind was working over what was supposed to be facing me and I forgot everything else, including my schools. Behind my back, none of my mentors (teachers) came to visit me…I am told that people don’t want to be around the dying—they have to face their own mortality. At any rate, once I realized I was not only going to live, but become better than before, I started to check into the status of my schools. I was told that a group of my “friends” had managed to steal my schools from under me and they left me with NOTHING. I was never paid the “Founder’s Fee” that the government demands of new businesses, etc. That’s what has left me without a penny to my name, otherwise I would be hounding Paul to sell some parts that I can’t get here, or maybe find someone willing to donate and ship a few special parts. My day finds me at the CPU (MS-DOS System-Windows-ME) and/or building. PCS-Edventures (The new name the thieves is now calling my schools (they dropped the name I created as a request of a 12-year-old boy who was dying, at the time, from cancer. It was called “PCS Centers for Advanced Learning,” All students liked it because one of their own named the schools. The adults in the company thought themselves more clever, so they changed it. Now I hope that my fellow brother engineers will know the part of my background that meshes with them.

I want to now present my recognition for 13 builders of note. I will name them later, as soon as I finish reviewing the rest of the group. I wish I could put a Red Star of Recognition for “above average” creation and innovation. One thing I have realized as I examine all of the models. I see a general influence of Peter in many of the models, as the builders first hit the site. As they remain, continue building, I notice there is less the “Peter Influence” and more “Individualized personality” starts to bring out the best. I credit much of this as proper leadership coming from Paul and I think that there are other “mentors” in the group willing to be self-less, drop what they are doing, and help the one seeking help. CONGRATULATIONS TO EVERYONE. I surf a lot these days and there is NO SITE that can compare with place that I call “home” and whose members I call my “brothers and sisters.”

If anyone would be interested in helping me get my hands on some LEGO Technic gears, etc. send me an Email and I will reply with the small list (I promise) that I drool over. I really miss the group building sleep-overs we held frequently, especially in the summer when we were outside cooking over a fire and sleeping under the stars and talking through the night about LEGO. [mcshane.patrick9@gmail.com]

@gimba96

I’m just working on one in my Tatra. If it turns out good, I’ll probably publish some instructions.

Great work!

I used it already a couple of times.

Only one question: Can you make an independent version?

@cody

Yes.

Yes.

so can this work with lego nxt

and how does it work like do u need two motors idk

@Beppe

The bevel gears usually can handle the torque from PF XLs. When using two PF XLs together, I tend to connect them directly. You’re right that there are small differences in their speeds and it’s a better solution to connect them through a differential, but a direct connection is simplier, stronger and less likely to fail under high torque.

Some more questions regarding high torque and gears. Can the bevel gears in the differential handle the high torque from the PF XL motor?

This question might not fit here, but I’ve seen that some of your models have drivetrains that are driven by two PF XL motors. In these cases, do you use a differential to distribute the torque from each motor to the drivetrain? Or do you simply connect them directly to the drivetrain? If the latter is true, do the motors “balance” each other well? I mean, even if the motors have the same speed on the paper it could differ in reality which could be a problem in a direct connection.

Thanks

Beppe

@Beppe

I think bevel gears are better in general, because their teeth design is more efficient. No, the PF XL can’t break the new u-joint, unless you add some gear reduction to it.

The topic of high torque on gears and drivetrains is an interesting one. After having read your gear tutorial I understand that the regular 24 teeth gear and the double bevel 20 teeth gear are the strongest ones. Are they equal in strength or is one of them the better one?

Can you tell anything about the universal joint? How much torque could it withstand? Would a PF XL motor break it?

@Beppe

Yes.

Do you mean these:

http://www.peeron.com/inv/parts/32072?img=22227 ?

@Beppe

Bevel gears are no good for large loads. Try knob wheels instead.

I’m having problem with the bevel gears in the steering axle. They slip when the load is getting large, for example when simply trying to push a heavy object with the car. I’m not using the differential since I don’t have one. The left and right side are simply connected with an axle and the axle is driven by a PF XL motor. The gear ratio is 1:1 from motor to wheel.

Any idea of what is causing the problem? Or are bevel gears and a PF XL motor simply a NO, NO? Can I expect to have the same problem with the bevel gears in the differential if I use one?

Thanks for these wonderful web pages!

@Ben

This is a different suspension of the same type, the way of using shock absorbers is the same: http://www.brickshelf.com/gallery/Sariel/Cat990H/dscn7018.jpg

Note that you don’t actually need absorbers for this suspension. They are only useful for improving stability.

@Sariel

Oh, OK, thanks. Do you happen to have any pictures showing it with shock absorbers placed on it?

@Ben

No. It rotates around longitudinal axle, thus allowing one wheel go up and the other go down when they meet an obstacle. Like here: http://www.brickshelf.com/gallery/Sariel/FaunSLT/dscn6202.jpg

@Sariel

So the whole structure goes up/down together?

@Ben

Because this is a pendular suspension, not an independent one.

I just don’t see where the ‘suspension’ comes in. There aren’t any shock absorbers or anything similar on it.

http://www.youtube.com/watch?v=wj-q9U22nuc

i made this using your system, but flipped the diff. around and used no wormgear to allow much more speed

thanks and they both look great

@blarson

These two, for instance:

http://sariel.pl/2009/01/colonial-marines-apc/

http://sariel.pl/2008/12/faun-slt/

what creations have you made with this design?

@blarson

Well you don’t.

how do i make one of these with the new differential

thanks

@legobuilder

Use the new 3 studs wide differential in it

@Sariel

I made some changes, have you read my mail?

@diego

Then use a fast motor or gears to accelerate it prior to driving the suspension module.

@Sariel

Yes, but it makes it very slow as legobuilder said before.

@diego

Because it’s a very compact way to transfer the drive to the differential.

why is it necesary to use a worm gear? can I avoid using it?

thanks.

thats a good idea but because im too young, I dont have the peices or the money yet-i have to wait till christmas!

OK, now I get it 🙂 what is the purpose of the clutch gear.

And the beam 3 problem I solved adding long pins as stoppers.

Hi.

Couple of question:

Is the instructions,missing a picture? 34?

Because the cluch gear doesn’t work. It makes the steering turn with a half bush with gears(?) but it doesn’t slip like clutch is design to do…?

And second problem is that the beam 3:s are pushing liftarms 2825 loose.

ok

@legobuilder

Perhaps try a stronger motor or reinforce the model.

if I speed up the input with gears the friction is so high that I lose power or my model is breaking in pieces:(

@legobuilder

There are dozens of possible solutions, and none of them is perfect. I’d like to know a really good one myself.

I want to build a big strong trtr but how can i made this trtr 4wd?

thanks

i now know how to do it.

@Adi

Then perhaps you should look for help at the Bricklink.

i really want to make this but i dont have a differential. i want to buy one from bricklink but i dont know how to do it.

@Sariel

ok I’ll try it:p

@legobuilder

Yeah, you can use a faster motor or speed up the input with some gears.

nice idea but it’s very slow any suggestions how I can made it faster? greetings legobuilder

Thx a lot dude 😉

This axle was very inspiered. But in my case not compact enought.