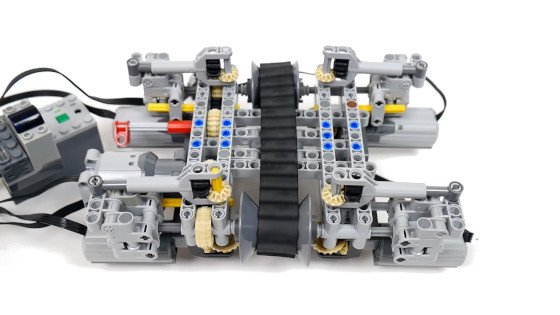

Variator Continuously Variable Transmission

Having recently designed a simple CVT, I wanted to try out a more advanced solution and recreated a real-life variator CVT. Instead of cones, variators use special dishes that are pushed together or pulled apart, while a wide elastic belt is stuck between them. The shape of the dishes means that depending on their distance from each other, the contact area between the dishes and the belt changes its diameter from larger to smaller and vice versa. There are two pairs of dishes, one on the input and the other on the output shaft, and changing their contact areas – which is usually done exactly in opposite to maintain the belt’s tension – effectively changes the input/output ratio.

The LEGO version was possible only thanks to the use of very specific LEGO pieces: the Scala 5×5 dishes and the solid rubber one-piece tread. The mechanism could theoretically work with just 2 motors: one for driving in, the other fort shifting it, but that would obscure the center of the transmission. I wanted to keep it well visible for the video, so I’ve used 4 individual motors for shifting. The resulting transmission design was enormous and impractical, but it worked. Just like my previous CVT, it was unfit for high-load applications because the belt would start slipping on the dishes under stress. The problem was made worse by the fact that the dishes don’t have traditional axle or pin holes, so the pairs of dishes weren’t actually connected by a common shaft. That meant that only one dish in each pair was actually directly driven, the other was just driven by the belt between them. In real variators, both dishes are driven and that certainly helps to reduce the slippage.

There are no instructions for this variant of the transmission as it’s very impractical and was only designed as a proof of concept.