Cat 854G

Model of a Caterpillar articulated wheeled dozer. Features 4×4 drive, suspension, remote steering, remotely raised and tilted blade, lights and custom stickers.

Datasheet:

Completion date: 17/12/2008

Power: electric (Power Functions)

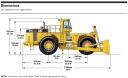

Dimensions: length 57 studs / width 30 studs / height 22 studs

Weight: 1.73 kg

Suspension: front – none / rear – pendular with shock absorbers

Motors: 4 x PF Medium

Another articulated Caterpillar vehicle. Partially similar to my earlier 990H front loader, but slightly larger and with different functionality. I wanted to use linear actuators instead of pneumatics, and that required more internal space that available inside a front loader. Therefore I decided to build a wheeled dozer, which offers more space inside the front hull’s part.

The drivetrain was simplier and more compact thanks to the use of new, 3-studs wide differentials. Only two motors were needed in the rear part of the hull, which could be therefore less massive and more realistic in size. The battery box was located in the same place, that is low behind the rear axle. It caused some problems with the weight distribution in case of the front loader, which did not have any heavy parts inside its front part. Here, another two motors were located above the front axle, so the weight distribution was much better.

The steering system was changed too. Earlier it was based on the horizontal 36-teeth gear braced in liftarms traversing the vehicle’s frame. This time, I wanted to try to save some space, and used a 12-teeth gear instead, with much weaker, yet more compact bracing. I was not satisified with the final result – the steering system worked, and supported model’s weight even when carried in hands, but the precision of steering was poor, and the central joint lacked stiffness.

As for the blade, I have attentively studied the construction and functionality of its real counterpart and decided to make it simplier and less functional. In the real 854G, the blade has the ability to turn to sides to a limited angle. Only a single hydraulic cylinder is needed to control this mechanism, but it meant that blade’s every point of attachment had to have two degrees of freedom. Thus the entire structure supporting the blade would become much more complex, and probably less rigid. Eventually, the blade was controlled by four actuators and turned out to be strong enough to lift the dozer’s front axle off the ground. The dozer performed reasonably well, except for the forementioned poor precision of steering. It could use a PF XL motor for drive to be able to push heavier loads, yet still the Medium motor provided a satisfactory torque.

The model was received much better than I expected. For me, it was merely a development of my earlier Caterpillar models, built partially for relaxation after the arduous work on the Colonial Marines APC model. Still, a considerable number of viewers expressed their accolade for the dozer.

whenever youy feel like making some, please do so!

i’ll send the instructions back to you, page by page so you can post your wonderfull models for the world to enjoy!

@Breteas

I don’t have in-progress photos.

that’s a fast reaction, thx!

btw, i’m a handy cg artist,

You mail me in-progress photos, i make instructions.

free. (it’s me hobby you know.)

Let me know, cheers,

Marko

@Breteas

Because they don’t want me to.

Right.

Me Lego when i was a kid.

Bought a couple of models (crane truck > big pf bulldozer > excavator and to complement my old stuff.. funny story, ask if interested..) Only 1 question:

WHY don’t you work for lego? Why? Why?

@Mihály Stépán

That’s the point – I never could use it because of insufficient room. But I will keep trying, e.g. with the Steiger Panther model.

have you ever tried steering an articulated vehicle with LAs? i think that would be a very realistic feature, provided there is room for them or it.

@buildabot

There are plenty of blueprints at the Caterpillar’s website.

where do you find the dimensions. awesome model!

Thx Sariel 😉

http://www.setechnic.com/Forum/topic1752-15.html

@GuiliuG

There are five. Search closely for photos.

@Sariel

Ok. But in the originale machine, i don’t see how the blade can move from left to right because they’re four cylinder, like your engine.

@GuiliuG

The blade can move from left to right in the original machine, not in the model.

Articulation is achieved with a horizontal 12-teeth gear, no cylinders. You can see it on the photos.

Tilt is probably needed since you don’t always use such a machine on perfectly flat surfaces. Sometimes you have to push material uphill, sometimes downhill.

That thy Moc I enjoyed very much, and now I want to do the same gear. For that, I have some questions to ask (again ^ ^).

-In true is it that the blade can move from left to right?

-The articulation of the chassis is accomplished through a cylinder or mechanically hydrolique?

As for the blade, I must say that I do not see the usefulness of the tilt, can you explain exactly what’s the point?

Thank you in advance for your answers

@Sariel

Really thx for you answer 😉

@GuiliuG

Perhaps you should work on the angle between the LA and the arm it raises. If the angle is too small, the LA will need a lot of power to move the arm.

@Sariel

Ok, because i have create a Moc : and La were hard to raise the arm when there are two reduction 12T-20T.

Look on your own ;-).

http://www.setechnic.com/Forum/topic1642-30.html

http://www.youtube.com/watch?v=nr5CtQDlrfg

but the arm should not carry much weight …

f you can tell me how it is done I would be very happy

Ps :

the sound of La in the end run is horrible

@GuiliuG

LAs are incomparably better, stronger and more precise than pneumatics. They are strong enough to be used without reduction. Pneumatics are worse, but more useful in some particular cases.

First it’s a beautiful Moc 🙂

I know that i ask a lot of question but i still have any question

-Do you prefer the La or the pneumatic “vérin?” ( i don’t know the word in english).

-Do you find that the La is weak and that i can’t lift any weight? Do you find that pneumatic vérin is better that La?

-Do you often use the la without “réductions?” ?

Thank you for your answer