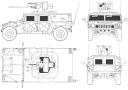

Humvee

Model of the Humvee designed for Truck Trial races. Features full independent suspension, portal axles, 2-speed remote controlled gearbox, lights, opened bonnet, doors and rear hatch.

Datasheet:

Completion date: 14/04/2011

Power: electric (Power Functions)

Dimensions: length 53 studs / width 26 studs / height 24 studs (not including antennas)

Weight: 2.319 kg

Suspension: full independent with portal axles

Propulsion: 1 x PF XL geared 8.3:1 (1st gear) / 3:1 (2nd gear)

Top speed: unknown

Motors: 2 x PF Medium, 1 x PF XL, 1 x micromotor

A little less than a year ago, I’ve built a simple Hummer H1 model designed specifically for the Truck Trial races. It turned out to perform better than expected, until the chain present in its drivetrain broke. I was relatively pleased with this model, until several months later I have come across a civilian H1 parked on a street. Having used this opportunity to inspect it as much as possible from the outside, I have come to the only proper conclusion: that my model was unsatisfactory.

While planning to build a new model – this time called Humvee to emphasize that it would be based on the military H1’s – I’ve decided to use the often-criticized black colour, because Humvees simply look excellent in plain black. I have also decided that I can’t simplify the suspension system like I did in my earlier model (which was suspended on simple pendular modules), but rather try and recreate the suspension system of the real vehicle. This is a tricky feature, as the Humvees have full independent suspension with portal axles. It’s fairly easy to build independent suspension or portal axles with Lego pieces, but it’s quite a different story to build independent suspension and portal axles. It means that Lego pieces that are designed for independent suspensions are pretty much out of the question. Instead, I had to create this kind of suspension using common pieces only.

Sophisticated suspension systems like this are usually wide – building the new model in the same scale as the old one was impossible. When I’ve tried the old Technic wheels that have best diameter/width ratio, it turned out that I can make the suspension 23 studs wide, including the wheels (my earlier model was 20 studs wide). Since the model scaled to the size of the wheels would be 24 studs wide, that suited perfectly – except that it meant abandoning the 1/13 scale required by the Truck Trial rules, which means that the model would not be classified in the race. I decided to accept that rather than to build another small model with simplified suspension system. Additionally, the minimum weight limit for the race has been changed from 1kg to 2kg, starting this year, which meant that my earlier model would be far too small to participate.

Another decision was to use a gearbox this time (my previous model had none), and my recently developed 2-speed heavy duty linear gearbox was an obvious choice. The gearbox design was so good that I wasn’t the only one using it in the race – Maniek’s truck used a gearbox like this copied with my permission.

Mechanically, the model used a custom independent suspension system with portal axles, with a 3:1 gear reduction at the wheels, and was driven by a single XL motors using a 2-speed gearbox with ratios 8.3:1 at lower gear and 3:1 at higher gear. There were four motors total: one for drive, one for steering (housed under the bonnet), one for shifting the gearbox (housed under the gearbox) and one micromotor for rotating the steering wheel as if it was actually working (which can be considered a cheat, but is not forbidden in the Truck Trial rules). 4 IR channels were used to control the model, with the fourth one used to turn on/off the lights remotely.

Aesthetically, I have focused on improving the shortcomings of my previous model and on modelling the features which are exclusive for the military Humvees. These included intake and exhaust snorkels, which I’ve never seen used in civilian vehicles, as well as the design of the whole rear end of the model, which is quite different in civilian versions. Namely, the location of rear-lights is different, and there are recesses for two jerrycans on the sides. Inside the model, there were two well-detailed seats in front and a radio station between them. There were no rear seats, as the space was taken by the gearbox control system, and the rear seats are usually folded in military vehicles, and thus can’t be seen from the outside. The model obviously included plenty of parts that could be opened: the bonnet, all four doors and the rear hatch which was split in two pieces: one opening upwards, another opening downwards. Just like in the real Humvee, the intake snorkel stayed in place when the bonnet was opened – this was one of the features I’ve missed in my earlier model.

The model performed well at the beginning of the Truck Trial race. It drove through the first section flawlessly, with lower gear used to climb uphill and higher gear used to descend downhill. The problems started at the beginning of the second section, where it simply stopped moving. As there was no easy way to locate the damage at all, I had to give up the race. It eventually turned out that I did a big mistake by meshing three 8-tooth gears in a row (which I did to split the main driveshafts in two, as required by the suspension system). Even though the gears were protected by 3:1 gear reduction at the wheels, they have shifted on their axles (as 8-tooth gears are slightly narrower than a single stud) and started to grind each other, severely damaging their teeth. Thus a careless drivetrain design resulted in six damaged gears and in the model utterly unable to move. Additionally, the front wheels had a strong tendency to bend, for no apparent reason. I would suspect some flaw in the suspension design, but the rear axle used almost identical design and the rear wheels did not bend at all.

Despite its obvious flaws, I consider this model a step forward from the previous one. It has proven my gearbox design reliable in the racing conditions, and it used a complex suspension system, to a moderate success. However, as I’m unable to identify the reason for the bending of the front wheels, it seems I should abandon this suspension design.

@Claire

Sorry but no.

Is there anyway i could get some instructions for this? I am looking to build my sister a Hummer as she has an H2 of her own but there are no good sets.

I am not looking to make it remote control just something that can sit there. I appreciate any help Please email if you can This is great btw keep it up

Claire

@Bob

I don’t know the current rules, frankly. But it wouldn’t win anyway.

But would that:

http://sariel.pl/2014/06/hummer/

be allowed in truck trial races? 😉

@Bob

I guess changing 8t gears to anything stronger would help. Besides, this particular Humvee sucks, that’s why I built this: http://sariel.pl/2014/06/hummer/

Sorry, if I was unclear. I ment this particular Humvee shown on this page, build in black with a weight of 2.319 kg, uses a two-speed gearbox, has full independent suspension with portal axles and has eight hard 6.5l springs (two per wheel) and has oldschool tires with a very hard compound 😉

@Bob

How can I know that without knowing what’s your model’s weight, wheel type or surface you want to drive on

Do you think that changing the drivetrain to something similar to this: http://thirdwigg.com/category/trial-truck/#jp-carousel-319

the model will have no drive problems? So changing the 20t gear with an 24t gear (one more stud to the left) and change the three 8t gears to two 24t gears. I hope you understatement what i mean…

@Damon

It’s “motor”.

Could you use a Xl moter instead if you take off some weight

thanks

@langero

Remotely, with PF Medium motor and two small linear actuators.

how did you shift speeds in the gearbox?

@gabry

Yeah, thanks to the gearbox.

Did that single pf xl motor give power enough to have good off-road abilities, even with all that weight?

@bob

And I mean, it doesn’t really make sense for driving a TrTr vehicle.

http://www.youtube.com/watch?v=uKWI656NLrE when you look at this, think: when you power just one motor the yelow part moves slower then when you power two motors. thats what i mean.

@bob

If the gear ratio remains constant, what’s the point of using just 1 motor and not all 4?

do you think that if i connect 4 xl motors with diffs to each other, it wil be a good gearbox for trtr? or just 2 xl’s? so when you power one motor, then you have the first gear, when you power two motors, you have the second gear…

@Sariel

Yes, you’re right. I think the best thing is to connect two different gearboxes each with two gears: the first will be controlled by an M motor, the second by a Servo one. As this I will have a two gears gearbox with the option of reduced gears, typical function in real off-road cars. I think I will put there two different battery boxes, ’cause as this the motors of the gearboxes won’t steal power from the driving motor. In your opinion, is this a good idea?

@gabry

Servo gearbox is not good for it. The only gearbox that would let you always shift gears while driving is the one with a transmission driving ring, but gearboxes like these can’t handle much torque. I’m afraid you can’t have both robust gearbox and shifting on the fly.

@Sariel

I have already built your jeep, but I didn’t love it because I made a big mistake and modified it, so in the end there was some backlash somewhere (I still don’t know where!). I wanted to build a different type of chassis. I fell in love with independent suspension and I didn’t want to lose much time, so I decided to ask you ’cause you’re one of the best builders I know. And now the gearbox: I know your gearbox, I tried and enjoyed it. This time I wanted to build a gearbox with being able to change speed without stopping the drive motor, but it’s an hard trick… Have you ever done it? I was studying your servo-gearbox, but I’m not sure if it’s good for TrTr… What can you tell me?

@gabry

Pendular suspension can be a better choice, it’s more robust and easier to build. Do not use differentials if you’re serious about off-road. You can try this gearbox: http://sariel.pl/2011/02/2-speed-heavy-duty-linear-gearbox/

And perhaps you should try to build my Jeep Wrangler just to get some experience with TrTr vehicles.

Hi Paul, I’m building a trial truck with independent suspension. I found many problems in the suspension system and in the steering, because I decided to use the classic components for independent suspension. Now I’m studying to put there a sequential gearbox… But in outdoor performances, are independent suspension a good system for off-road cars? Is there much backlash in the differentials? And what can you recommend me for the gearbox?

@bob

Here, bob: http://lmgtfy.com/?q=portal+axles

what are portal axles?

@Daan

Yes – the photos and description you see here.

I really wanna build this have you something that shows how you made it?

@thirdwigg

mhm… yes, cumbersome, it takes almost 20 studs, you should know it. I don’t think that your system is good for sariel’s hummer, but it’s only my opinion… you have done a great job, sorry if I have hurt your feelings XP

@thirdwigg

what does it mean?

@gabry Cumbersome?

Ehi Sariel, I’ve found somebody that has made classic independent suspension with portal axles. It’s a cumbersome system and it’s not good for your Hummer, but it’s nice. If you are interested you can see it here: http://thirdwigg.com/2012/07/30/international-ftts/img_8327

Mhm… sorry I don’t know what I write… I know it; I only have some little problems with English… Forgive me, I’m 14 years old 😀 Your Hummer is cool, end. Sorry for the time you spent with me.

@gabry

Yes, they are lighter. As for the other things, here’s where you’ll find all the information you need: http://google.com/

Can you tell me the differences between portal axles and pendular suspension?

P.S.: Oh, I also wanted to ask you something other: are rechargeable battery boxes lighter than classic battery boxes?

@gabry

No, they are completely different systems and real Hummer has only independent one.

But aren’t portal axles and pendular suspension the same system? Can you explain me the difference? I thought that this Humvee had pendular and independent suspension, isn’t it true?

@gabry

Real Hummer has independent suspension so I didn’t want to use a pendular one.

Ah I know. But couldn’t you make a different pendular suspension system connected to the chassis with a normal axle for driving and cardans for the steering system? You should only put the steering components on the rear axle of the set 8070, do you know what I mean? And this should be more or less 19 studs wide, like your axles. You should only change the wheels. I’m sorry to stress you Sariel, but I’m too curious, I know. I hope you will forgive me…

@gabry

They are wider than my system, which is bad because a Hummer with wheels sticking out to sides would look weird. And they don’t allow portal axles because you can’t attach gear hubs to them.

What? Why don’t they allow portal axles? And I think they aren’t wider than your system, their width is of 6 or 5 studs. Isn’t it good?

@gabry

Because they’re too wide and don’t allow portal axles.

Very nice! Why didn’t you use the classic independent suspension components? As this the wheels couldn’t bend, you know

@Jerry

No.

is there instructions?

@Paul

No, I don’t.

How did you attach the axles to the chassis? Do you have a pic of the underside?

@Bernardo

There is no Ackerman steering system here.

?

@Bernardo

I didn’t.

how did you build the ackerman’s steering system?

Oh ok, well thanks anyways. 🙂

@Nick

Thank you. No, I could not, especially since this suspension proved defective – it would be just a waste of time.

Do you think you could post instructions for this type of suspension (independent, driven, steered, portal axle) in the ideas section. I tried to build it based off of the video but I coulden’t get a goo enough view. Once again just the suspension, not the whole vehicle.

P.S: Great build! 🙂