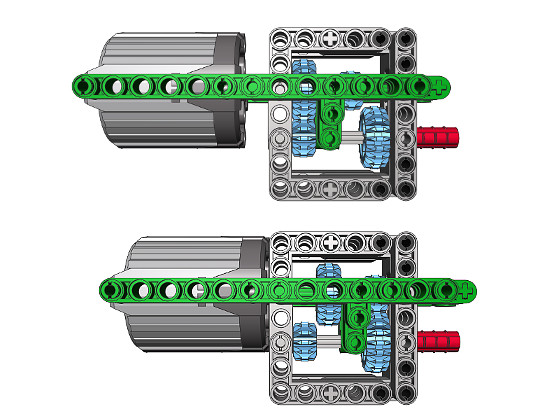

2-speed Heavy Duty Linear Gearbox

Compact, simple gearbox designed for use in Truck Trial races and high-torque applications. Step-by-step instruction and a two drive motors variant included.

Last year, the continuous development of the Truck Trial vehicles in our country resulted in the common use of gearboxes. Since the power-to-weight ratio of each vehicle decides how much points it gets, it is favourable to reduce this power to minimum. This is where gearboxes come in handy – they allow to use less motors, or less powerful motors, increasing gear reduction when needed, and decreasing it when less torque is needed. Without the gearboxes, all vehicles would have to use a gear reduction high enough to climb obstacles, which results in reduced speed and in a waste of time when e.g. driving downhill.

The loads exerted on vehicles’ drivetrains in our races are so high that it’s very difficult to use a gearbox with driving rings. In most cases, it results either in the driving rings disengaging under load, or in mechanical damage to them. Therefore it’s a common practice to use simple linear gearboxes, with as few gears as possible, as most vehicles can do very well with just a 2-speed gearbox. The need for reducing amount of gears to minimum resulted in integrating the drive motors into the moving parts of the gearboxes, so that the motors slide as the gears are changed. The idea, introduced by Emilus in his Truck Trial models, eliminates the need for complex transmission mechanisms between sliding driveshaft and stationary motor, and has practically no disadvantages, except for slight shifts of the vehicles’ centre of gravity caused by motors’ weight.

The following gearbox has been developed from a version used in my Fiat SPA35 Dovunque model. The Fiat’s gearbox has failed during the race, but it has given me the opportunity to observe exactly what are the causes of its malfunction. Based on this experience, the new gearbox has been reinforced in all the crucial spots and is practically immune to mechanical damage, while still being relatively compact and simple.

I have provided schemes, views from various angles and a full instruction for the gearbox, as well as a scheme and views of a version using two drive motors instead one. Note that the sliding mechanism has not been included, because my experiences with Fiat have shown that it’s best to make it part of the chassis close to the gearbox, that part of the gearbox itself. Still, building such a mechanism should be fairly simple, as all it has to do is to slide the central bracing a single stud back and forth, and keep it in place. The mini linear actuators are one of the many options that can be considered here.

@Sariel

The gearbox is great and im building something like a trial truck

Thanks

@Goshik

You slide the part with the motor forward and backward by 1 stud.

@Sariel

And also im a big fan of your creations

@sariel

The gears sometimes grind and how do you make it change gears

@Sariel

ok thanks for the advise

@tony

Use the 2-speed gearbox, or no gearbox at all. 4×4 drivetrain is not a problem, the problem is the suspension system, because it sounds like you don’t have parts to make it and without suspension your truck won’t work well outdoors.

hi sariel big fan of your lego ideas and cars that you make i wanted to make a truck to go outside and go through hills and stuff but i dont have alot of pieces i was thinking of making a 2008 chevy suburban i want it to work good so i have two questions

the first question is that should i use a 3 speed gearbox or the 2 speed gearbox that u made

the second question is that i dont have any shock absorbers or suspensions and was hoping you have another way of making heavy duty 4×4 drivetrain

i would appreciate it if you can give me some advise rather than me making something from you since some of the ideas i have made i cant use on the truck so please reply to this thank you

from tony

@Alberto

You look at it wrong. Output doesn’t change its position – input does, together with the motor. The gray frame that braces the gearbox should be fixed and not moving – instead, the gearbox moves through it.

Hi Sariel, I just wanted to ask you one thing about the gearbox. The gearbox is nice, but I saw that the output change the position when I change the gear ratio. How can I solve that problem?

hey i just want to say this is an awesome creation, i love the 2 motor version

@MrBronzegoat

It’s all explained in the text.

hey man please tell me how to switch the gears/accelerate

I put this in one of my cars and it was SO strong unlike my gear boxes that fall apart as soon as it goes.

tanks anyways @Sariel

@jordan thomas

You can connect it any way you like.

i think he means like can it be directly driven to an axle with out raising it up and using a gear system if you still don’t understand look at the under body picture of your South Africa MRAP and your gear box it raised up and uses two gears to connect to the drive system he means directly to the main drive shaft to the @Sariel

thanks this gearbox won me a truck trial

@johnboy104

No, it doesn’t change itself. I have no idea what is this “ground level” question about.

How does the gearbox change by itself? Do you have to shift it to high and low ranges? Does it work on ground level?

@Grant

Yes, of course. You don’t need to ask 🙂

Great Instructions! May I translate this article also?

( In fact one LEGO fans on our forum had already finished the translation, and we will add the author and url to this site. )

when i first tried to make a 2-speed gearbox on my own, not knowing how they worked, i ended up with a 1:1 ratio for the low gear and a 1:5 overdrive for the high gear. it didnt work very well

@Erik Bussink

Yes, it does. The gearbox is too simple for the extra torque to get wasted.

How does the heavy-duty work with two engines vs one. Does it truly add nearly twice the torque ?

@zeke labelle

Linear actuators? Motorized lever? Rack and pinion? Scissor mechanism? There are dozens of possibilities.

it works good so far but how can i get it so i don’t have to change the gears by hand and i don’t have any pneumatic’s plz help

@Sariel

ty

@zeke labelle

You can do anything you want with it.

is it ok if i use it on my wheeled tank

Its the best gearbox for vehicles i have ever seen on most LEGO forums including YouTube etc Robust,convienient changes and relatively small.Great work!!!

@Tanner T.

Not at all. That’s why I published these things in the first place – to be used by others.

Would you mind if I used this gear box and your 4 speed manual in a vehicle I am working on?

nice gearbox it works well compared to a gearbox i tried to make

@Mehley

Well, you can always use gear acceleration between the LA and the motor. I used miniLAs in the Humvee and it was slow, but I didn’t need it any faster there.

Hello Sariel! Eariler you mentioned, that a small actuator would be slow for changing gears.. however, in your Hummer you used this mechanism 🙂 As I saw, it worked great, and wasn’t slow at all. Do you think it can work with a big size LA fas enough?

@NikJan

They are NOT mounted together. Look closely at picture 6, they have two separated axles.

Is it possible that the motors get damaged when they’re mounted together like in picture 5?

pity it would be nice!

@claudio forlani

It’s large, it would be difficult to fit in the Jeep. You would have to modify the Jeep a little, perhaps make it longer. It will certainly affect aesthetics.

Basically I want to figure out whether you can insert this change in the jeep wrangler.(without affect the aesthetics and performance).

It is understandable that you don’t understand, but I didn’t want to disrespect to an important person like you.

@claudio forlani

Claudio, it’s hard to understand what you’re asking.

then okay for all models that you have built without moving anything?

Perhaps it is a secret but I’ve told you how to change gears, I build a mechanism like you did with humvee?

@claudio forlani

Errr…. there’s no need to remove or raise anything.

how do you do to change gear model?

removing or raising the seats, it could be mounted on the jeep rubicon?

Po co, skoro większość rzeczy opisuję po polsku na LUGPolu?

Sariel… a może zaczniesz prowadzić bloga w dwóch językach ? ;]

@Naturalbornuser

MLCad: http://mlcad.lm-software.com/e_default.htm

I LDView: http://ldview.sourceforge.net/Downloads.html

Sariel w jakim programie robisz lub polecasz robić schematy, chodzi mi o projektowanie wirtualne takie jak np w powyższej instrukcji?

@bob

Both will work.

Is it ment to motorise with a linear actuator or with something pneumatic ?

@bob

Not really, that would require a very different design.

can you make this with 3 speeds?

@adithya

Nope.

@Sariel

anything even smaller than that?

Correct, Thank you very much. I was having some trouble trying to explain exactly what the problem was. Thanks though, your always a big help whenever i have problems building.

@Trevor

Perhaps you’re looking for this: http://sariel.pl/mocs/scania-dump-truck/10.jpg

Yes I could, but it still wont switch gears is my problem. The initial problem is with my drive shaft because it wont allow me to push forward into the next gear. I need something that is like a +1/-1 stud set up to allow the gear box to shift fluidly with out the pulling out the axle of pushing the axle through my rear chassis and into the other knob gear.

@Trevor

Can’t you just swap gears?

Sariel,

I was wondering if you have a solution on how when the gear box switches into the higher gear it also moves one stud length further out. If i connect the gearbox to the frame of my truck it wont switch gears because it just pushes the frame and starts to grind gears. Is there any type of easy solution to this problem.

@adithya

Take your pick: http://sariel.pl/tag/gearbox/page/2/

Hey, do you have a gearbox wich is a two speed one, but more compact?

@Sariel

Many thanks for the tip, I will try this method to change gears! 🙂

@Mehley

Small actuator will be slow for this. In my Fiat truck, with similar gearbox, I was using a 4-studs long pushing lever driven by a Medium motor reduced 24:1 (with a worm gear driving a 24-tooth gear). It worked pretty fast.

Thanks for sharing this efficient gearbox mechanism! I have just build it, it works great! However, changing the speed should be made fast, in order to prevent the gears from stucking. Did you realized this problem as well? Anyway, is there any chance to change speed remotely fast? Maybe a fast geared small actuator can do this?

@Sariel

I just realized you can’t put bushes there, yes.. sorry 🙂 just looked at it now, and saw it.. but yesterday I’ve been looking at photos and didn’t see this. awww…

Can’t wait to see how it’ll work ! 🙂

@Mike

There can be no bushes Mark. If you put bushes there, the gearbox won’t have space to slide.

As for the meshing gears, I don’t think it really affects the friction. But it’s still good to keep the gears meshed properly, or they may be more prone to mechanical damage.

Oh and one more thing. I know that these 20 and 12 toothe gears tend to cause friction when given a one-stud wide space like here. You know, the older e.g. 16t gears are narrower at the teeth, but these new ones aren’t. Once when I used them I had to put half stud bushes on each side of the gears to prevent this.

Do you consider this friction minimal, or can it cause significant power consumption in a trial truck?

The concept of this gearbox I think is great, I think this year you’ll have much better luck, this and other developments will bring better results! 😀

Do you use one stud long bushes between gears to prevent them from sliding on the axle?

I’m curious because I rarely see them on your MLCad drawings, but I guess you always include every part you use in the real thing.

Nie przejrzałem wszystkich zdjęć .

Sory !

@DoKnEs

Popatrz tu na prawy górny róg: http://www.brickshelf.com/gallery/Sariel/ideas/2speedHDgbox/6.png

Jeżeli masz zamiar zbudować trialówkę z mechanizmami zwalniającymi takimi jak w przednim moście od twojego Jeep’a to radze Ci je zmienić na jakieś inne żeby koła się nie rozjeżdżały każde w inną stronę .

Jeszcze jedno na zdjęciu http://www.brickshelf.com/gallery/Sariel/ideas/2speedHDgbox/5.png

widać że silniki są złączone jednym Axle’m w ten sposób gdy włączysz dwa silniki w jedną stronę bo inaczej przy rozwiązaniu jakie widać na zdjęciu się nie da knob który będzie odbierał napęd nie będzie spełniał swojej roli ponieważ będzie kierowany w duł albo do góry .

Pozdrawiam

DoKnEs

As always, your diagrams and explanation really help Technic fans with understanding complex mechanisms. Your work is really helping to advance the overall level of Technic models worldwide. Thanks for sharing!

@DoKnEs

Dokładnie tak działa ta skrzynia. A przełożenie między nią a kołami można sobie dobrać pod masę konkretnej trialówki.

Wiem .

Napisałem tak ponieważ moim zdaniem jedynka powinna być wykorzystywana do podjazdów i pokonywania innych trudnych przeszkód , a dwójka do jazdy po równiejszym terenie .

@DoKnEs

Wystarczy że dodasz redukcję za skrzynią. Przecież nikt nie powiedział, że wyjście ze skrzyni musi iść od razu do kół.

Skoro ma to być skrzynia biegów do Truck Trial to moim zdaniem przełożenie jest niezbyt .

Uważam że bieg 1 powinien mieć przełożenie 1:3 a pieg drugi 1:1 .

Skoro napisałem coś źle to przepraszam .

Pozdrawiam

DoKnEs