Grassgrinder

Vehicle built for outdoor testing of custom tracks. Features simple suspension system and skid steering using RC unit’s steering output.

Datasheet:

Completion date: 27/06/2014

Power: electric (RC unit)

Dimensions: length 50 studs / width 31 studs / height 14 studs

Weight: 2.2 kg

Suspension: pendular bogies

Propulsion: 2 x RC motor geared 3:1 from slower output

Motors: 2 x RC motor

LEGO ready-made tracks have plenty of advantages, but they are also rather fragile and easily damaged when driven outdoors on anything harder than snow. Ever since the 2L beams came out, I had idea that they would be perfect for custom-built heavy-duty tracks. This vehicle was built to test them.

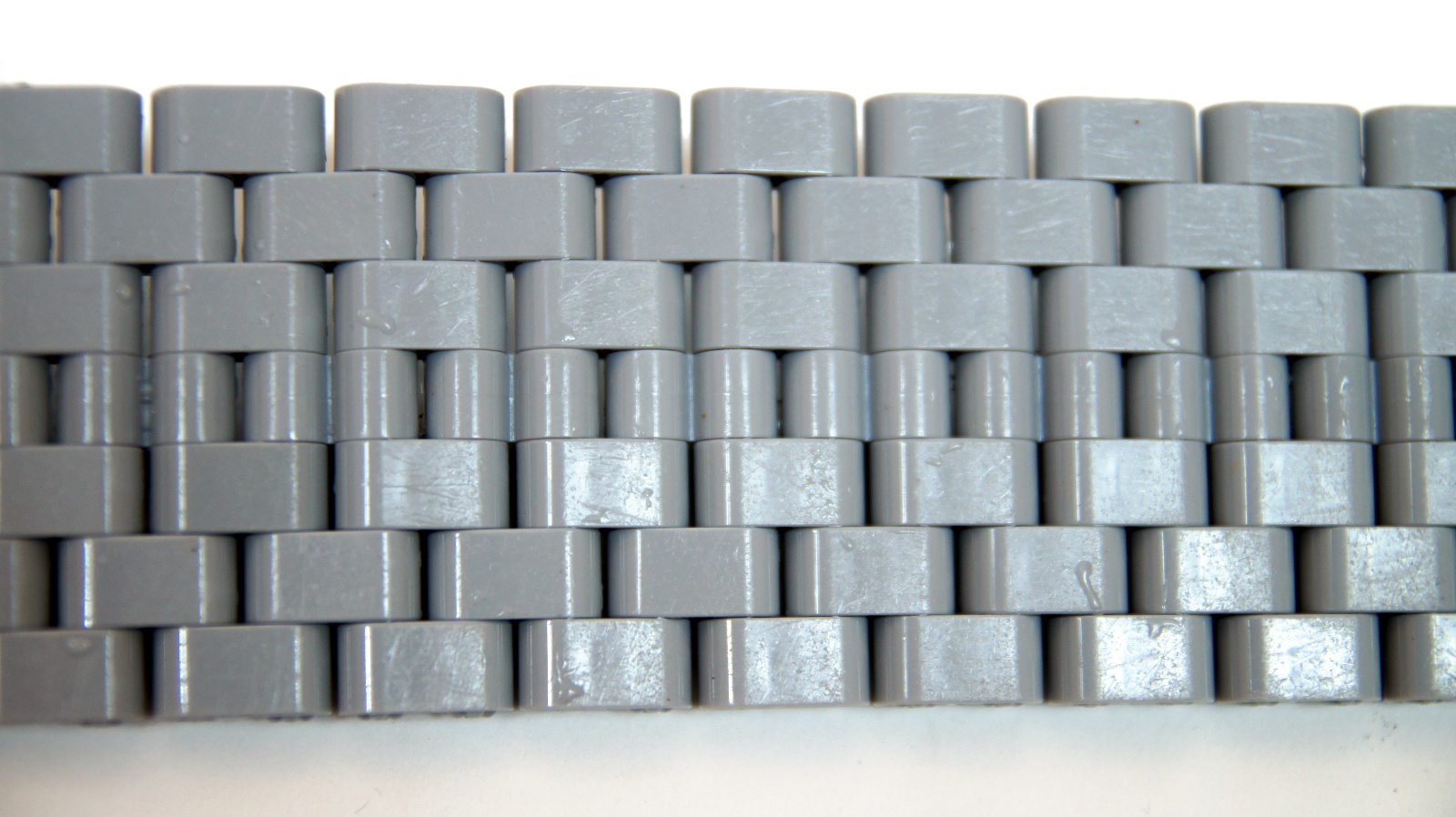

The tracks were 7 studs wide, made to fit two 62.4×20 wheels, one stud apart. They consisted mostly of 2L beams held together by 7L axles, with double connectors in the middle acting as a guide that remained between the two wheels and prevented the track from slipping off. The resulting track was very flexible, extremely robust, and had superb traction thanks to the proper tension and vehicle’s weight. It was also quite silent – I would say it produced less noise than the LEGO 5L wide tracks. On the downside, it was over 2.8x heavier than them.

The vehicle itself was extremely simple, as I wanted good performance and minimum weight. It was built around a RC unit, with two RC motors connected through switches. The switches were kept in ‘on’ position by rubber bands, and arranged so that they would be engaged by RC unit’s steering output. They output would simply turn one switch off when turning, and when it returned to center, the switch was returned to ‘on’ position by the rubber band. Thus steering right was done by simply turning off the right motor, and vice versa. It should be noted that the tracks proved to have large inertia, and the motor did not stop immediately when turned off – rather, it slowed down gradually. Also, it was not possible to make zero degree turns, because that would require two motors running in opposite directions rather than one motor running and the other stopped.

The vehicle was fitted with 10 double road wheels in each track. The first four were suspended on simple pendular bogies, two wheels each, while the rearmost wheels acted as sprockets. Thanks to excellent traction of tires inside the track, no actual sprocket was needed – just wrapping the track around the wheels was sufficient to drive it. I haven’t noticed a single case of the tracks slipping on wheels.

When tested outdoors, the Grassgrinder did very well on tarmac, sand, gravel, cobblestones and pavements. It was somewhat slowed down on grass, and practically impossible to steer on it. With more torque, steering would be possible even on grass. Traversing some hard obstacles, such as stairs, clearly put a lot of stress on the chassis, and the tracks had tendency to rip some grass off and had to be cleaned repeatedly. The tracks looked bad after driving for about one and half hour, but most of the wear proved to be dirt – when washed, the tracks showed very little actual wear.

The vehicle was fun to drive and performed better than expected. The tracks proved very durable and reliable, even if heavy. Given that they can be easily modified to be wider or thinner, and used with various wheels, I’m sure I will be using this kind of tracks some more in the future.

@Christian

Pendular bogies. It’s dead simple, just take a good look at the photos.

Hello Sariel! That is quite an interesting and practical design, but how did you make the suspension system for the wheels?

@Hansen

Bricklink, for example.

@Namaro

Over 10 meters. You can buy it at Bricklink or eBay.

How long is range of controler? and where can i buy set for all motors and controlers?

Where can you purchase those 2l beams?

Extremely impressive! I love the solution for custom tracks; very innovative.

@sonaar

I think these gears have teeth spaced too close. Besides, I haven’t used any sprocket, so why should you?

Nice design indeed. Do you consider using old Expert Builder gears like [a href=”http://www.bricklink.com/PL/g21.jpg”]g21[/a] as sprockets is a good idea? Otherwise we need custom built robust sprocket.

@forge

No, there is no RC motor in this set.

@Sariel

i had a quote…. anyways here it is

http://www.ebay.com/itm/LEGO-Racers-8378-Red-Beast-RC-Remote-Control-Car-/251545318385?pt=Building_Toys_US&hash=item3a9144f3f1

@forge

What kit?

Very impressive.The suspensionworks great!

i am currently on a hunt for lego rc motors. does this kit on ebay contain them? thxs 😛

@andy

I don’t think it will do much to improve grip, which is already excellent.

i know that if you use rubber pieces it’ll wear down but can you put like half lift arms half rubber?

@Woyta

I actually think it sucks. It’s expensive, weak and will probably wear down within a day. And these tracks already have excellent grip.

I prefer variant with rubber axle connector. More grip. 🙂

@Miles

Skid steering would be much more difficult with just wheels.

@Pranav

Some of my early tanks have pendular bogies, I think. For the later ones I’ve been using torsion bars.

Which of your other namely models use pendular bogies as well? While the idea behind the tracks is stellar, I can’t help but admire the well-synergizing suspension. Most of your tracked models, I assume?

Would this work with just wheels? I know the idea of this vehicle is to test the tracks, but since the “sprockets” are actually tires, it should provide sufficient grip, or am I missing something?

@Reinhard

The tracks can work with anything. They just need strong motors.

Wow! Thats such a good idea, I tried to make tracks like that but i didn’t have enough pieces:( Could it be made to run with PF XL motors and IR signals?