2-speed Automatic Gearbox

My first automatic gearbox, based on a design by Misha van Beek, but improved and simplified.

I always liked the idea of incorporating automatic gearboxes into large models, unfortunaltely such gearbox designs are unique and I only know two by Misha van Beek. While both are advanced and show great knowledge of the author, they are also large, complex and none changes gears smoothly. I thought that the new, small differential may give me a good opportunity to create a more useable design. I had three simple goals: to make a gearbox that is small, simple and above all capable of changing gears without jamming. The two first were easy, the third one took some time to work out, but eventually I got exactly what I wanted.

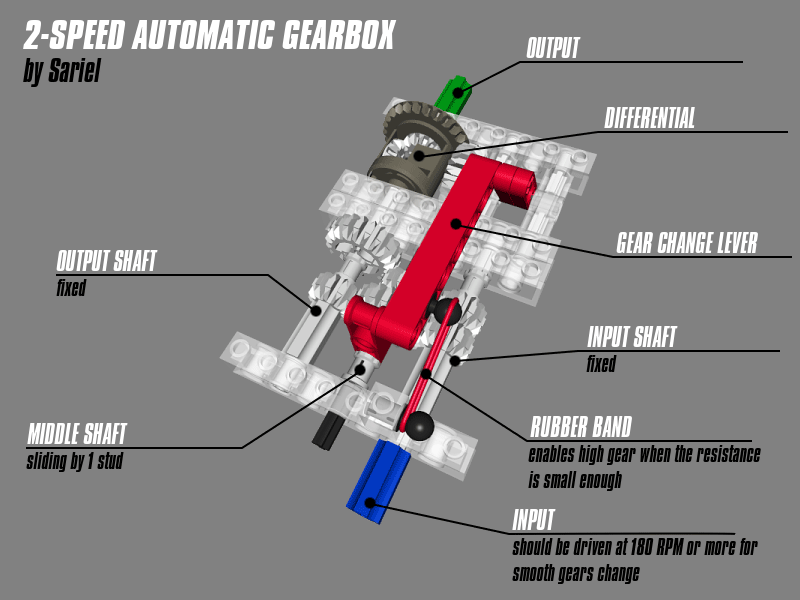

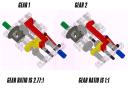

The basic idea of Misha’s design is to use a differential to transmit the drive in such a way, that if the resistance of the output grows, it will at certain point trigger the gearbox to switch to lower gear. Thus the motor will have a better chance to overcome the resistance, and once it’s done the gearbox will switch back to the higher gear. Whereas Misha has taken this idea further, and created gearboxes with more than just 2 speeds or with no fixed gear ratio at all, I considered two smoothly operating speeds a better option than three or more jamming ones. The lower gear has 2.77:1 gear ratio, and the higher one has 1:1 gear ratio. I have been experimenting with more different ratios, but as the difference increased so did the tendency to jam while changing gears. The 2.77:1 ratio difference should be sufficient in most cases, and it offers a reasonably smooth functioning of the gear change mechanism.

The construction of the gearbox is really simple. It fits into a 8×12 studs rectangle (plus the middle shaft protrudes out by 1 stud on higher gear), and axles of any length can be put into input and output without taking the gearbox apart. Moreover, the horizontal liftarm which servers as the gear change lever, provides a lot of space to adjust the tension of the rubber band accordingly to the weight the gearbox is supposed to handle (namely, the towballs it sits between can be put closer or further from each other).

You can see the smooth functioning of the gearbox in the video. I have also provided a parts list (just 45), an LDR model of the gearbox at lower gear and higher gear, plus an exact instruction which can be found below.

@johnboy104

Probably.

What about if your output dosen’t run to 180 rpm, will it be a hard shift then?

@wyatt

Because it’s way too fragile.

@Sariel More rubber bands?

why Wont you use this in your trial trucks?

Ah, nicely done. I tried several of these a while back, and my best one is this: http://wishfulcoding.nl/buildinginstructions/gearbox.pdf

@neamerjell

There is a three-speed design of such a gearbox existing. The problem is, it rarely stays on second gear, and the problem would increase with more speeds.

@Sariel

I figured the transmissions might try to work against each other like that. I wonder how difficult it would be to make an automatic transmission using the same concept as this one, but with more than two speeds. My first guess would be that the resulting size and complexity would make it impractical for use as anything but a proof of concept. Still, it would be a neat thing to try.

@neamerjell

Yes, bevel gears are way better suited for linear gearboxes. As for coupling two automatic gearboxes, I think it wouldn’t work well because they would keep affecting each other. They are both torque-sensitive and at the same time they manipulate the amount of torque in the drivetrain, so they would interfere with each other and probably keep switching back and forth all the time.

I’ve seen your stuff around Brickshelf.com over the past few years, and I’m completely blown away by the ideas you come up with.

What do you think would happen if you made a second transmission, with a different ratio, and its input connected to this transmissions output. Would it make a four speed automatic transmission, or would both parts try to shift at the same time when resistance is met?

Also, I’ve noticed when I tried to build linear transmissions with 24, 16, and 8 tooth gears, they end up grinding and binding. Do the bevel gears you used help with this?

I successfully built the transmission with the old differential.

@ghzz

It can be the rubber band, or some pieces are put together too tight. Yes, the gearbox is supposed to work only clockwise.

@Sariel

i use the same motor as you, i even replaced the batteries with new ones. Maybe it’s some friction on the axles, or i don’t know what.

what is more, i have the same problem as Alex (it works only clockwise 🙁 ).

@ghzz

Perhaps you should drive the gearbox at higher speed.

Hi Sariel,

I made this gearbox with ALMOST the same parts, the only difference was with the differential case: i used older one and that old gear with curved crown. It works, but during every shift the gear are cracking (i mean they are making that awful sound). Can I blame the differential case for that?

@Sariel

no i didnt try this,and thanks for suggest me. 🙂

@Sunil

Did you try BRICKLINK?

hey i want to make this gear box, but i am unable to find the parts like gears. Can anyone help me???

so it’s more a matter of saving energy in the gearing… ok, thanks

i had the doubt because they have the same power.

@Ambro

Then you’re talking about different motor or looking at wrong specs. The 4×5 studs motor has 2000 RPM, 0.45 N.cm torque and 0.9 W mechanical power. PF Medium motor has 275 RPM, 3.63 N.cm torque and 1.04 W mechanical power. So the Medium motor has over 8 times more torque, and despite your motor’s theoretically similar mechanical power you can’t really make up for it by gearing because any substantial gearing with Lego gears has low efficiency.

by the way, i found this page:

http://www.philohome.com/motors/motorcomp.htm

seems that my motor is more powerful than the power-function-M, even if i thought that it is really weak.

@Sariel

ok thanks.

maybe i’ll try with the one i have, even if my diff seems to be 4 stud long. i should buy some new ones on ebay or the site you use.

the big problem is the motor, i’ll see if i can get a new one

@Ambro

It will work with any differential whatsoever. As for the motor you mentioned, no, it’s terribly weak and there is no gearing that could make it match for newer motors.

may i ask a question?

is it possibile if i use the old differential (not the very old one, the 24-16 teeth dark grey one)? if so, is it better if i use the 24-teeth weird gear to connect the diff?

another question: i only have the really old motor, the parallelepipedal one sized 4×5 studs. i know that it rotates much faster than the new ones that you use, but has much less torx. are they comparable if i just gear it down? should i use a worm-gear or normal gears are enough?

i’m asking because if i have the opportunity of making something enjoying and complex, it is worth taking LEGO down from the attic.

@mescalinum

No, I don’t think the speed would affect its sensitivity.

what would be the impact of driving the axle at faster speed, and reducing it after the differential? would it increase the sensitivity of the gear switch?

If you adapt it to, it will.

will this work with the old differential

Of course not. Why would I put a differential in there if it wasn’t needed?

could you make it without the differential ?

I want to use my PF car for smooth surface racing not just for speed trials…the gearing is quite high which makes it a bit sluggish in lower rpm:s.

How do you make an automatic 2-speed gearbox that changes into high gear when the motor reaches a certain rpm and you want the car to keep accelerating?

i made this gearbox but it doesn’t work, can someone please help me?

sorry, i mean the 2nd one.

i really don’t know which one is newest.

@Pontoos

Perhaps you should look at it, because it has the new differential right in it.

will it works with new differential?

@Alex

Firstly, I don’t think this gearbox was ever suitable for a Truck Trial vehicle. It’s simply too complex and fragile. Secondly, it’s not possible to use driving rings. Driving rings have a neutral position, and whenever a gear is shifted, they need to go through it. The problem is, in the neutral position the motor is disengaged from the output, which stops an automated gearbox from working. I actually tried this solution, and the only result was a driving ring jumping from high gear to neutral position and then back to high gear. It never shifted to low gear, because the neutral position stopped it from doing so.

I have just tried your gearbox on a TT. The problem is that I use a PF XL motor which turns at 146 RPM – less than the 180 RPM you advise. Therefore gear change is mo more perfectly smooth.

Do you think you could develope a 2 speed automatic gearbox using the Driving Ring (www.bricklink.com/catalogItem.asp?P=6539) and the 16 Tooth Gear with Clutch (www.bricklink.com/catalogItem.asp?P=6542)?

@Joe

No. Two motors are more powerful and just as fast.

but two moters are fast and just as powerfull

@Alex

In that case you’re right, I’m sorry.

@Sariel

I think you misundertood me. I meant the the gearbox works only if the vehicle is moving forward and it doesn’t work if the vehicle moves backward. This is how it looks like from the video. And it makes sense because I don’t see how the differential could trigger the lower gear moving in the other direction.

@Alex

No, this is completely wrong. I suggest you watch the video.

This gearbox can change to the lower gear only if the motor does not change direction of rotation. Otherwise it will stick to the higher gear. Is this correct? Thanks

@Joe

But you can switch to lower gear and get extra torque.

extra power ? for when you go up a hill

@Joe

I think you could, but what for?

like that could you make it switch on another moter instead of changing gears?

@Jeff Cheng

Try this one: http://www.brickshelf.com/cgi-bin/gallery.cgi?f=104297

could you possibly create a 2 speed auto with the slightly older differential (without the angled teeth), as this gearbox will only work with the newer version. thanks

@Sariel

i will, if ill get that 8297 suspension =)

atleast it would trigger at downhills and when speed would be high enough..

@Chili

No idea, go ahead and give it a try.

@Sariel

How about 10-60n.cm-ish on my f1 race car im trying to build?

if i would adjust the rubber to so high it wouldnt trigger while pulling its weight(1kg?)

@Chili

It can be adjusted, but no, I don’t think it could handle the kind of torque you have in trial trucks.

Can the point of gear switch be adjusted with rubberband type/many bands?

If so would this work on trial trucks etc..?

@blarson

No, I don’t.

do you think this setup could be used with large wheels

and what is the name of the song that is played in 2-speed Automatic Gearbox

thanks

I built this with lift arms and found it worked exactly as described. The only problems I had were the two gears on the center axle would gradually creep forward, and occasionally both would engage and the system would bind. another half-stud in length would likely fix the binding issue, though high rpms do pretty much minimize the risk. I think I could have solved my problem with the gears sliding about with a better match between the gear and axle (searching for a tight fit).

I think more gears could be added by simply lengthening the input side of the mechanism and using a few more gear matchups, but this would negate reliability and smoothness.

Overall, lovely concept. I must make it a little more compact and put it in my mini trail truck that I am working on. (same idea as a trial truck, but something like half the size.)

sorry i found them

hi i dont no were the instructions are for the 2speed automatic gearbox could you help? thanks

@bobsurankle

Very interesting, thank you for bringing this to my attention. I’ll have to try something like that, but I’m afraid it doesn’t work well at low speeds.

I found this on couple of days ago…:

http://www.youtube.com/watch?v=LBIbMWq1ktI

http://www.youtube.com/watch?v=uqf4D5juBJs

http://www.youtube.com/watch?v=Q1G2SylEllg

…do you think that you could make it smaller in any way?

Thanks.

@wessel

I don’t think an automated gearbox would work in the Truck Trial. There are actually very few gearboxes that would do that. As for the shifting, I encountered no problems with that so I’m not sure how could I solve yours.

I think your main subject was to make a gearbox fit for a trucktrial?

So everyone, don’t make drag cars!

anyway, could you make the red shift part more horizontal, so that it matches with the gears? The shift connector keeps pulling at the wrong side (top left instead of left) and makes the gear shift piece bend a little where it should slide. This makes a lot of friction!

@RjbsNXT

I probably could, but it would be large.

i realise this is only effective for one direction, other wise there is no gear switching; i was wondering if you could use this is connection with your direction sensitive gearbox to create a 4 gear fully automatic gear box?

@jonas

In most cases it’s the fault of rubber band being too tight or too loose.

hi i can not get it to work

@Simon

MLCad.

Which program do you use when you animate the lego-ideas?

@crawlerdude

In my brain, very likely.

This is awesome where do think up ideas like this

@Sariel

ok thanks sariel.

@legobuilder

If you need a higher speed, some gears after the gearbox should do it.

You can also design a gearbox with a high speed switch?

@Sariel

yes, i think that will happen if you place them behind each other, but, I’m going to try out! first I’m going to get all the necessary parts from bricklink.

@max-o-l

This is possible, but it may be very unreliable. There is no way to make sure that the gearboxes will be triggered one by one. More likely they may start to trigger each other.

sariel, in theory, if you put like…3 or 4 of these automatic gearboxes

after each other, would it work then still too? becouse then you can have a 8 automatic gearbox, but is this even possible?

@Eugene

Since they’ve chosen to sell their ideas for money, that would be pretty much like stealing from them, don’t you think?

I’ve seen this automatic gearbox that LPE Power has made. Can you try to find out how it works. Here is the link: http://www.lpepower.com/content/heavy-duty-automatic-transmission-10

have you ever tested it on a real car, cause I have been working with previous models of you and it doesn really work that good. perhaps this model does work better, because it lookes pretty strong etc. Although the resistence necciserely to make it go faster isn’t that much. Right I just see that you have put it on a vehicle, so I did not really make a point, but I”m too lazy to delete everything xD

@Arnau

I’m sure there’s a FAQ on the LDraw’s or MLCad’s site somewhere. You may use Google too.

If I download the latest parts update, will I get all the parts, or do I have to do every update?@Sariel

@Arnau

Try updating your parts library from here: http://ldraw.org/

Pneumatic hoses are not modeled as far as I know, but the cylinders, valves and other stuff is.

I’ve downloaded MLCad, but I can’t find pneumatics in it. Do you know if you can use pneumatics with MLCad?

thank you very much, you have much attention for your fans!

i gonna try this immediatly!:D

@sergio

Here: http://www.brickshelf.com/cgi-bin/gallery.cgi?f=73968

About 10 seconds of using Google is all you needed.

ok thanks, but i don’t have the new differential but the old one, how i can make a automatic gearbox with that?

@sergio

Yes to both questions.

is it possibleto make a 3 speed automatic gearbox?

and works this for a 4×4?

@Jimbo

It can be done with any differential, it will just be larger and more complex.

with your 2 speed automatic gearbox, can you make one for the old diffs

but alsa a great idea ilke it!!!!!

While I haven’t obtained a differential I’ve found that the gears are to close together in your build and kept jamming. To compensate, I worked on elongating the design so that there is more room between gears to give space for the gears to not overlap. It’s a bit messy but I think it’s getting there. Thanks for sharing!

Just built this gear box to test the shifting. Worked OK, but I also found mine to struggle a bit with shifting to the lighter gear. I think the rubberband I have is a bit to strong. Gonna try with some other ones tomorrow.

Keep up the good work.

@Nicholas Carter

Perhaps you don’t drive the input fast enough? You have used double bevel gears in the changing mechanism, I guess? Aren’t they perhaps worn? I’ve heard from a number of people who have reconstructed this gearbox that it worked smoothly for them.

I built this just about exactly the same but with the older differential (because I dont have the new one). The problem was that it kept on getting jammed when I tried to change gear. Any suggestions?

Nice and compact. I have to try to build that today. Should fit fine for most cars.

Great work, I like the video!

Wow, I´m really amazed. That´s some great shit! 🙂 Can´t wait to try this out. Once again, great work!

@Agent567

There where you can get any other part: http://www.bricklink.com/

Where can you get the diferential?