Abrams M1A2

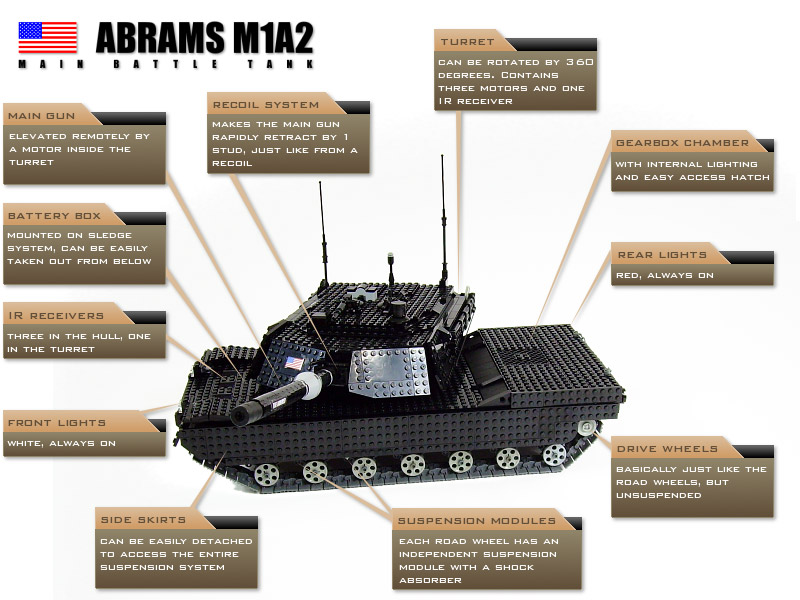

Successor of the Challenger 2 model. Features advanced suspension system, dual 2-speed remote controlled gearbox, remotely rotated turret and elevated gun, main gun recoil mechanism, battery box sledge mounting system, custom stickers and lights.

Datasheet:

Completion date: 17/10/2008

Power: electric (Power Functions)

Dimensions: length 74 studs / width 26 studs / height 18 studs

Weight: 2.83 kg

Suspension: full independent with separate shock absorbers for each road wheel

Motors: 5 x PF Medium, 2 x PF XL

While building my Challenger 2 model, I got plenty of new ideas, some of which had to be dropped because of the limited size of the model. I don’t usually like to build two constructions of the same type in a row, but in this case the number of these ideas was so large that I’ve immediately started to build another, bigger model with newer treads system.

The suspension system was pretty much the same, except it used tread wheels of the newer tread system, seven road wheels on each side of the tank, and shock absorbers of three different, mixed hardnesses (compared to two hardnesses in the Challenger 2). This time the hull size was kept accurate, and was not deformed by the suspension system. The radius of the road wheels was slightly smaller than imposed by the scale (3 studs instead of 4).

The drivetrain, on the other hand, was completely different. It didn’t use any form of subtractor – instead, a single PF XL motor drove each track via a driving ring-based 2-speed gearbox. The gearbox could be actually called two gearboxes, as it consisted of two identical, independent modules. Each of these modules was controlled by a PF Medium motor, which resulted in the possibility to remotely change gears for left and right tank’s track independently. The gear ratios of both gears differed three times. If we include turning in place, it means that the gearboxes offered 10 possible combinations of the model’s turning radius. This was, however, somewhat inconvenient in practice, and the separate speed control of each XL motor would certainly be a better solution.

Gearbox was located at the back of the hull, inside a special chamber with internal lighting and 8×8 plate with grill on the top, so that it could be easily seen what gears are currently selected. The top grill plate was mounted in such a way, that it served as an easy access hatch in case if any problems with changing gears should occur (which never happened). Nearer to the middle of the hull were two XL motors, and then two Medium motors that controlled the gearbox (both with safety clutches). Front part of the hull housed a battery box with a special sledge mounting system. Thanks to that system, the box was firmly installed inside the hull, but could be removed from below in a matter of seconds. Moreover, the system was only slightly larger than the box itself, and didn’t require any extra parts to be attached to the box. Finally, the very front of the hull housed three of four model’s IR receivers.

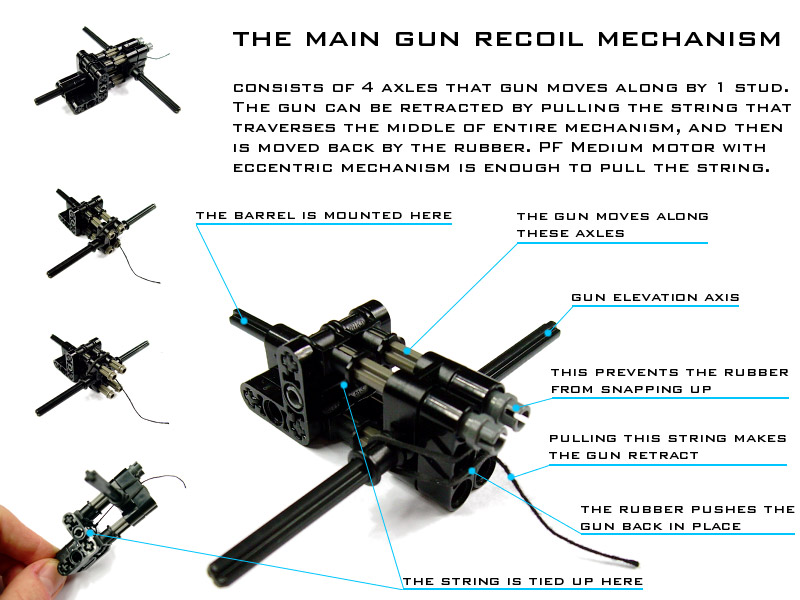

The turret’s construction was based majorly on the turret of the Challenger 2. It housed three Medium motors, one IR receiver, and a single linear actuator. It was powered from the hull via two wires, which granted large rotation freedom. One motor with a safety clutch was used to rotate the turret, and it could be rotated through 360 degrees, although not as smoothly as the Challenger’s turret because of the worse weight distribution (the rear of the turret was much heavier than the front). The other motor powered linear actuator that controlled the main gun’s elevation, exactly in the same way as in the Challenger. The third motor controlled the main gun recoil system. It consisted of a motorized eccentric mechanism with a string attached in such a manner that the string was continuously pulled back time by time. The other end of the string was attached to the main gun’s cradle, which provided 1 stud of longitudinal movement and contained a rubber band that worked against the string. Thus, with the recoil system engaged, the main gun was pulled back by the string, and then moved back forth by the rubber band. It happened in continous cycles, regardless of the gun’s elevation. One drawback of this solution was that the gun was somewhat unstable, and vibrated while driving. This effect could be, however, greatly reduced in case of a shorter and lighter gun.

I was very happy with the final look and performance of the model. While unstable main gun looked a bit ridiculous, the tank made up for it with the flawlessly working suspension and drivetrain. Using shock absorbers of different hardnesses was a good solution, although the last pair of road wheels was troublesome to suspend (it needed hard shock absorbers to not yield to the model’s weight while driving forwards, but such absorbers only worked a little bit on the obstacles). Driving the model with two XL motors was a good idea too, it is clearly seen on the video that such a drivetrain was quite powerful, despite the tank’s weight. It should be noted that it was difficult to make the model turn in place on any not-really-smooth surface, probably because of the tracks’ length. Still, it was quite an advanced and well-functioning model, and for some time I have even considered it an ultimate level of how far a tank model can be developed. Which was obviously not true 🙂 Additionally, it was my first model photographed with professional lighting and against a professional background – especially the lighting greatly increased the quality of final pictures.

If you make me one, I’ll buy it.

@Emil

No.

Great job Sariel.

Is there a battery box in the turret?

@mauler

Erm… if you haven’t noticed, you can stack the cable connectors one on another. And they stay powered this way.

hi!i have a question:how did you link 7 motors to one battery box?The battery box has only one contact where you can connect a cable;i knew I could link at most 1 receiver to the battery box and 2 motors to the receiver…thank you very much

@kacper

No.

can you send insrtuctions for tank?

kacper 😉

@Fabian

Everything is on the photos or in the description.

Hi I have got a second question.

How do you made the suspension?

Thank you for the last answer.

@Fabian

Here: http://www.brickshelf.com/cgi-bin/gallery.cgi?i=1510282

can you make some photos of the 2 speed gear box pleas

That is awsome you should make more of them and sell them i would want to buy one 🙂

@manne

With a crank.

How do you get a motorto pull the string in the recoil mechanism?

@Sabrejack

It’s simply enclosed between two liftarms on hinges. I think it’s well seen on the second photo.

Could you tell us more about your battery box sledge mounting system?

@Julian

Of course they have, and the colours are supposed just to indicate that.

Ok first of all GREAT JOB but i didnt know the shock absorbors have divrent levels of hardness? Do they have difrent colors to indicate that.

Hope you and Mr.Fluffy have a great day

Julian(The Lego Kid)