Caterpillar 740 Ejector

Model of a Caterpillar articulated hauler with a rare load ejection system. Features a 6×6 drive, remote controlled gearbox and pneumatically locked differentials.

Datasheet:

Completion date: 30/09/2011

Power: electric (Power Functions) / pneumatic (internal motorized pump)

Dimensions: length 81 studs / width 22 studs / height 30 studs

Weight: 3.225 kg

Suspension: pendular

Propulsion: 2 x PF XL through a 4-speed gearbox

Motors: 2 x PF XL, 6 x PF Medium, 2 x micromotor

I have always considered an articulated hauler to be a “must build” for any Technic builder. So when I found a Caterpillar hauler with a load ejection system very different from the standard one, I decided I have to model it. What makes this machine unique is the fact that it does not dump load the way the regular haulers do – instead, its cargo hold remains fixed to the chassis at all times, and inside it there is a crosswise blade that moves forth and back, ejecting the load from it. Such a solution allows to unload the hauler underground, for example in mines where low clearance doesn’t allow to unload a regular hauler, and it makes the hauler more stable while unloading, because its center of gravity is not elevated.

The basic problem with the model was the fact that I started building it, but then I was too busy to continue for several months. I have finished the model some 4 moths after starting, and I was really bored with it at the time. It made me ignore several things – for example, I didn’t bother to make any stickers or to model the railing on cabin’s sides more accurately. The front part of the cabin was also inaccurate, with mudguards made bigger to house two motors controlling the gearbox.

With plenty of space available inside the model, I have installed a number of mechanisms in it, although none very complex. The propulsion system consisted of 2 PF XL motors connected to a 4-speed remote controlled gearbox. I have used my compact gearbox for that, with 2 Medium motors attached, each motor controlling one transmission driving ring. The motors were connected so that by engaging one ring, they disengaged the other one – an idea by Mbmc137. The gearbox worked better than I anticipated, working flawlessly on all 4 speeds and just occasionally disengaging at 3rd and 4th gear. This was not much of a problem, as it took one move of a remote lever to engage the gearbox again. The only downside of the gearbox design was that the gearbox itself was elongated, with 2 motors attached to its sides, forming a big “+” shape which was difficult to include in the chassis.

Each of the three axles was driven through a differential, which could be locked pneumatically, using my compact differential lock design, by a remote-controlled autovalve, housed under the bonnet, next to the gearbox. The chassis was pendular and unsprung, just like in the real vehicle, with the front axle locked to the cabin, and being able to rotate together with it relatively to the central articulated joint. The two rear axles formed a simple pendular tandem, and a section of extendable driveshaft was used to drive them in any position. The suspension worked well, although I was unable to show it on the video, as the double bevel 12-tooth gears in the front axle got grounded too much while driving with a heavy load of beans, and I was unwilling to disassemble half of the chassis to replace them.

The steering was carried out by a Medium motor installed in the rear half of the chassis, controlling 2 small linear actuators. I was concerned if they will be strong enough to steer such a heavy model, but they proved quite capable at it.

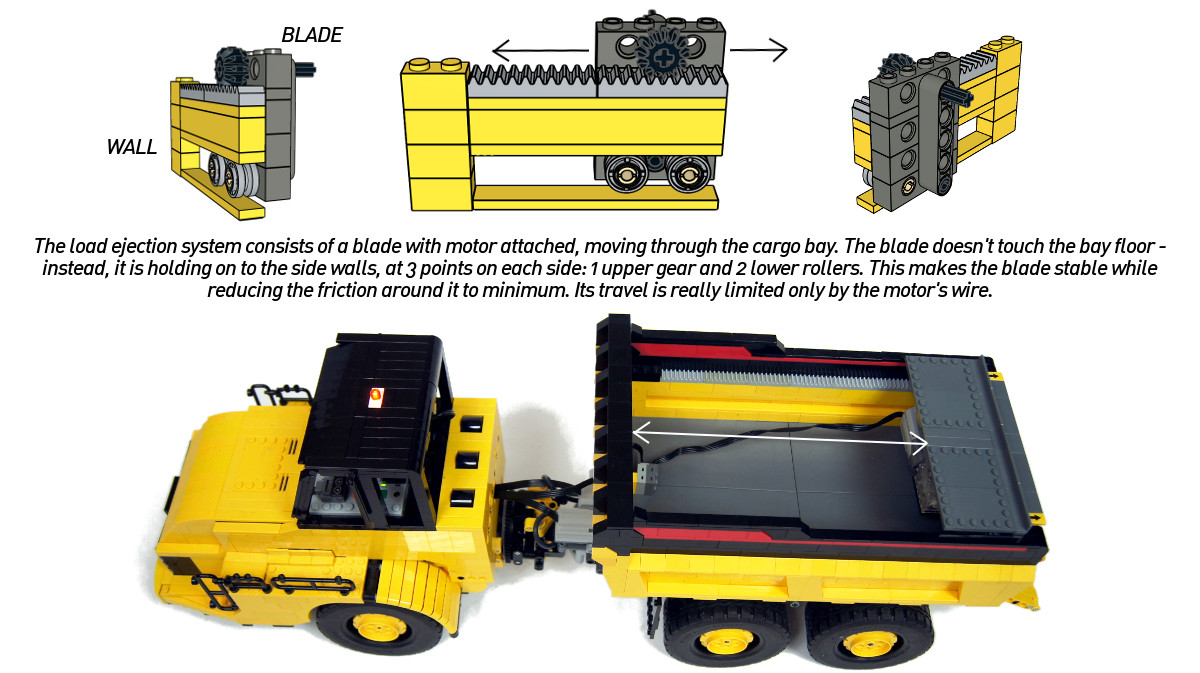

The load ejection system was the only real challenge in building this model. The original blade is moved by a big hydraulic cylinder – something not possible with Lego pieces, which is why I decided to drive the blade with a motor attached to it instead. Placing the blade in the cargo hold was tricky – I soon learned that it can’t touch the floor because of the massive friction, and that it has to touch each side wall at several points to keep the blade moving straight, as any difference in positions of its left and rear end would make it slanting inside the hold, and thus stop it. In the end, I suspended the blade on the side walls without touching the floor, using three points of support on each side: a gear on top, and two rollers below. The three points formed a triangle and kept the blade stable at all times, and the gear was driving it by rotating on racks. There was very little friction in this system, and the blade was able to eject a full hold of beans without putting any real strain on its motor.

The tailgate of the cargo hold was motorized too. It was opened and closed by another Medium motor, located under the cargo hold, and synchronized with the blade motor. Unfortunately, there was no space to add a clutch to it, so the tailgate kept skipping when it reached the fully open or fully closed position.

The two last motors were installed inside the cabin, along with the 8878 battery. One of them was rotating the steering wheel, while the other one was moving a lever on the driver’s seat side forth and back, making it looks as if they were working instruments.

I was rather happy with the model, even though bored as well. It provided an opportunity to put a number of various mechanisms to test, most importantly the complex remote controlled gearbox, and I was quite satisfied with the load ejection system. At the same time though, the model had a weak drivetrain and a heavy construction, with the central articulated joint suffering from stress.

@Sariel

Thanks;) Why “of course”? The other one is good too; for example, Sheepo uses it in his mini sequential gearbox…

4207456, of course.

in the gearbox, did you use the 4207456? or did you prefer the 4512360?

@Tony Stone

Either works.

How would you balance pendular suspension? Shocks or flexible tubes?

Nice work Sariel!

For some reason I find this model incredibly hilarious. 😛

@Appleipodwolf

I did. You just have to click the link.

Could you make instructions for the 4 speed gearbox ?

Great Modell

Greetings HACKz

@Toni

Thank you, but instructions are not possible. I took the model apart already.

Very ambitious model! I would like to build it myself. But my skills are not enough despite your excellent fotos. What do you think about putting building instructions into the net. I think it´s not only me that would want also to pay for it…

Such a thing to do with a hamster… 😉

nice model with lots of functions, it’s good to see something in yellow for a change 🙂

@gabry

There have been some articulated haulers in our Truck Trial races. They were unstable and they had very, very bad approach angle.

wow! THIS is very cool! the eject system is fantastic, and the steering is awesome! But in the video the truck doesn’t seem so functional as it should be in theory… another small defect is the “not perfect” driving system… although this your new MOC is very pretty. P.S.: the steering system of this creation could be useful in a trial truck, because you don’t need steered axles. E i tuoi criceti sono inquietanti, Sariel XD

I will subscribe to give your poor pet liposuction. Please tell me how to sign up. By the way, nice work on the 740. A fine example of the superior Sariel system of play.

@Sariel

I know what locking differentials are supposed to do, I only asked why in this case because there was no footage of the vehicle outdoors or on an off-road surface.

@Qwertyuiop

Locking differentials always have the same function – disabling differentials to allow driving out of a slip situation. I was unable to show it in action though, due to the failing drivetrain.

Great work as always! Definitely worth the wait. I never would have thought that a driving ring gearbox such as the one used would be able to move such a huge model. Also, why did you add locking differentials to it? They don’t really seem to do much. Can you tell me what their planned function was?