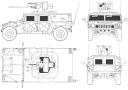

Humvee

Model of the Humvee designed for Truck Trial races. Features full independent suspension, portal axles, 2-speed remote controlled gearbox, lights, opened bonnet, doors and rear hatch.

Datasheet:

Completion date: 14/04/2011

Power: electric (Power Functions)

Dimensions: length 53 studs / width 26 studs / height 24 studs (not including antennas)

Weight: 2.319 kg

Suspension: full independent with portal axles

Propulsion: 1 x PF XL geared 8.3:1 (1st gear) / 3:1 (2nd gear)

Top speed: unknown

Motors: 2 x PF Medium, 1 x PF XL, 1 x micromotor

A little less than a year ago, I’ve built a simple Hummer H1 model designed specifically for the Truck Trial races. It turned out to perform better than expected, until the chain present in its drivetrain broke. I was relatively pleased with this model, until several months later I have come across a civilian H1 parked on a street. Having used this opportunity to inspect it as much as possible from the outside, I have come to the only proper conclusion: that my model was unsatisfactory.

While planning to build a new model – this time called Humvee to emphasize that it would be based on the military H1’s – I’ve decided to use the often-criticized black colour, because Humvees simply look excellent in plain black. I have also decided that I can’t simplify the suspension system like I did in my earlier model (which was suspended on simple pendular modules), but rather try and recreate the suspension system of the real vehicle. This is a tricky feature, as the Humvees have full independent suspension with portal axles. It’s fairly easy to build independent suspension or portal axles with Lego pieces, but it’s quite a different story to build independent suspension and portal axles. It means that Lego pieces that are designed for independent suspensions are pretty much out of the question. Instead, I had to create this kind of suspension using common pieces only.

Sophisticated suspension systems like this are usually wide – building the new model in the same scale as the old one was impossible. When I’ve tried the old Technic wheels that have best diameter/width ratio, it turned out that I can make the suspension 23 studs wide, including the wheels (my earlier model was 20 studs wide). Since the model scaled to the size of the wheels would be 24 studs wide, that suited perfectly – except that it meant abandoning the 1/13 scale required by the Truck Trial rules, which means that the model would not be classified in the race. I decided to accept that rather than to build another small model with simplified suspension system. Additionally, the minimum weight limit for the race has been changed from 1kg to 2kg, starting this year, which meant that my earlier model would be far too small to participate.

Another decision was to use a gearbox this time (my previous model had none), and my recently developed 2-speed heavy duty linear gearbox was an obvious choice. The gearbox design was so good that I wasn’t the only one using it in the race – Maniek’s truck used a gearbox like this copied with my permission.

Mechanically, the model used a custom independent suspension system with portal axles, with a 3:1 gear reduction at the wheels, and was driven by a single XL motors using a 2-speed gearbox with ratios 8.3:1 at lower gear and 3:1 at higher gear. There were four motors total: one for drive, one for steering (housed under the bonnet), one for shifting the gearbox (housed under the gearbox) and one micromotor for rotating the steering wheel as if it was actually working (which can be considered a cheat, but is not forbidden in the Truck Trial rules). 4 IR channels were used to control the model, with the fourth one used to turn on/off the lights remotely.

Aesthetically, I have focused on improving the shortcomings of my previous model and on modelling the features which are exclusive for the military Humvees. These included intake and exhaust snorkels, which I’ve never seen used in civilian vehicles, as well as the design of the whole rear end of the model, which is quite different in civilian versions. Namely, the location of rear-lights is different, and there are recesses for two jerrycans on the sides. Inside the model, there were two well-detailed seats in front and a radio station between them. There were no rear seats, as the space was taken by the gearbox control system, and the rear seats are usually folded in military vehicles, and thus can’t be seen from the outside. The model obviously included plenty of parts that could be opened: the bonnet, all four doors and the rear hatch which was split in two pieces: one opening upwards, another opening downwards. Just like in the real Humvee, the intake snorkel stayed in place when the bonnet was opened – this was one of the features I’ve missed in my earlier model.

The model performed well at the beginning of the Truck Trial race. It drove through the first section flawlessly, with lower gear used to climb uphill and higher gear used to descend downhill. The problems started at the beginning of the second section, where it simply stopped moving. As there was no easy way to locate the damage at all, I had to give up the race. It eventually turned out that I did a big mistake by meshing three 8-tooth gears in a row (which I did to split the main driveshafts in two, as required by the suspension system). Even though the gears were protected by 3:1 gear reduction at the wheels, they have shifted on their axles (as 8-tooth gears are slightly narrower than a single stud) and started to grind each other, severely damaging their teeth. Thus a careless drivetrain design resulted in six damaged gears and in the model utterly unable to move. Additionally, the front wheels had a strong tendency to bend, for no apparent reason. I would suspect some flaw in the suspension design, but the rear axle used almost identical design and the rear wheels did not bend at all.

Despite its obvious flaws, I consider this model a step forward from the previous one. It has proven my gearbox design reliable in the racing conditions, and it used a complex suspension system, to a moderate success. However, as I’m unable to identify the reason for the bending of the front wheels, it seems I should abandon this suspension design.

@arnaud

No, I could not.

could you make a building instruction ?

Please 🙂

great hummer

in my opinion this is a very good job as far as modelling of hummer is concerned, but your

suspension is even better. i think i have spotted the problem and you should retry it. wathcing your facebook photo (http://www.facebook.com/photo.php?fbid=10150184864253696&set=pu.243748243695&type=1&theater) you should replace pins 6558 and 87082 with a 32138 (bricklink catalog codes). this will prevent the wheels from bending as it locks while 87082 is free to rotate. I am not certain about this but as you have said truck trial is about evolution and you should take a look. ecxelent job anyway

Howdy, champ. i built your gearbox (aeroshift) and i put the motor output as in input, and i think you could make a really cool racer out of it!

@wyatt

No. I don’t know if you noticed, but it didn’t work well.

can you make instructions for the front Independent suspention? im using it for my next trial truck thanks

@Trevor

Regular PF extension wires.

Hello Sariel,

I have recently purchased 2 Micromotors off of bricklink. I thought that the motors would work with the regular PF cables but it seems that they do not. I would just like to ask what extension cables did you use to run your Micromotor. Thanks.

@finnian mcintosh

I already have. There’s a link to it in the description, you just have to find it and click it.

hi i was just wondering if you could give me instructions on the hummvee’s 2 speed gear box

@MeCho123451

Congratulations.

i mean this in the nicest way, but I think I might of made a better steering remote than yours only in that it is 1L shorter in width. it is the same is the one in Track Turbo RC but with a double bevel gear (large) and in between the actual remote and the 1×3 thin beam is a 1×2 thin beam and a “Blue Technic, Axle Pin with Friction Ridges Lengthwise”. it is really hard to explain in text, hopefully you can understand

@Jerry

What makes you think I have a LDD file for it? Do you seriously suspect that I have an instruction or LDD file for everything I build? I find it hard to understand where this idea came from.

@Jerry

i mean like you must need a blueprint or idea for this hummer.

Can you send me a LDD file

@Jerry

What instructions? Where would I get it from?

@Jerry

my email: meharveyjerry@gmail.com

Can you please send me the instructions? Tks

@fraser

I’m glad you like it.

@Sariel

hello again ive just come back from holiday again

and ive just brought 1 IR remote 1IR reciever and 1 rechargeable battery box

and ive fixed my jeep WOW! your jeep is good ive never failed a test 🙂

@Robin

I use half-stud wide beams.

Hello i am german. how do you do with the body of lego? the normal Lego parts are an even number long and the techic parts are an odd number length. sorry for the poor translator. 😉

@fraser

Here: http://www.bricklink.com/catalogItem.asp?P=58123c01

@Sariel

in what section? i cant find anything in there!

@fraser

Bricklink?

hey sariel i have just come back from holiday in Italy and i have not been building recentley

and i have still not got an IR reciever. where can you buy them?

@mindstorm addict

This one: http://www.bricklink.com/catalogItem.asp?P=44772c02

Wich whell and wich tire would be the best for a off road (I don’t care of the look )

@Sariel

hey sariel thx for the tips, ive fixed it and guess what. it was a matter of laze because i didnt put any 3 st thing behind from where you have the 8 to 24 tooth gears i guess it pushed down so much that it was jamming in to the 8 T gear.now all i need is 8878 reachargeable battery and an IR reciever because of the roll incident i said earlier. Thanks

this is such bull shit luck! my IR reciever brock a few weeks ago when i had just finished a really heavy truck chassis and it rolled over and then it broke 🙁

@harley

Did you try checking my Ideas category or Download section?

hi i have recently discovered you and your amazing! i am good at building machanisms with lego but not really that good at aesthetics. me and a freind are planning to build a truck that contains a 2 speed gearbox(automatic or rc), pendulam suspension with 4wheel drive. do you have any tips on how to get 4wd, steering and drive on a pendulam suspension?

@fraser

Make sure you built it properly, check if every piece is exactly in place and no pieces are worn. You’re the first person with such a problem so the problem is most likely with how you built it.

sariels lego jeep wrangler is a good car in the video but when i build it its rubbish thanks to

clonking in the rear axle when turning or when it meets an obstacle any tips?

thanks il see if i can buy it

@kyle m

Here: http://lmgtfy.com/?q=lego+8297+set

hi again i ve been reasearching trial trucks for several months and i was wondering if you could send me a email picture of the suspension on 8297

thanks i hope it works

@kyle m

Well, you have to use suspension components from the 8297 sets, that’s it.

i am 13 and im making my first ever trial truck and i am using your 2 speed gearbox(the recent one) and i was wondering if you could make a post on how to build a lego driven independant suspention for a trial truck. thanks

@Sariel

Yes i was not sure i just mentiioned it, you know the best what is wrong or not.Another solution for this problem i think would be to use flatter tires next time,they will probably bend along with the rest structure and ameliorate the condition.LOOKING FORWARD TO NEXT MODEL!!!

@panos

No. The way to “discharge” it is by making tires slip. The problem with the front wheels has nothing to do with that, especially since it occurred mainly while driving straight.

Well real vehicles use differentials to adjust the torque output to each wheel.I think that for a truck trial oriented vehicle, the current lego differential is just a disaster so you did well not to install such systems.But when steering ,one wheel (inner ) has excess power and the only way to ”discharge ” it is by bending the parts .So i think that the problem you are facing is partially due to that.

@panos

I didn’t use differentials at all.

Did you use differentials in both pair of wheels?

@SGT Jensen

Yes, I know. I have 8880. I have all the newer suspension & transmission parts too. I just didn’t want to use them.

*transMission

Hello. Regarding individual steering&suspension, the Supercar 8880 has got it. But it’s steering is also weak… But LEGO has made brikcs for that kind of transission…

best regards

@Tanner T.

These wheels are 10 studs in diameter.

I am working on a Defender and had the same problem with the front wheels. It can be fixed by instead of having only one steering arm, make two. Also what size wheels did you use? I’d like to use them on my Defender 90 🙂

@tom

4×4 drive is always better than RWD outdoors because you have power on every wheel. So if your RWD performed better than your 4×4, it’s because your 4×4 was bad.

lately i saw disadvatantages in 4×4 drive. I made a rear wheel drive car that worked better outside then most of my 4×4’s. maybe it’s because MY 4×4’s suck or that it’s just useless at sometimes, you tell me ?

@pironski

I use my brain.

that is very cool hammer 🙂 how you make 4×4 ?? please tell me ;]] my skype is:cool19977 ;pp

@Sariel

yeah, try the monorail 🙂 lay down the tracks along the trial track and go for it 😀

@fifer253

So I should enter everything now?

why don’t you enter the monster truck in the next trial truck race, you entered this and its not to scale.

@NXTnut9

Yes.

Neat 3D models and effects/transitions were they all done in Pinnacle Studio 14?

@Krika99

I don’t think so. It would have to be really huge if scaled to these wheels, and I think the look of these wheels is completely wrong for the Hummer.

I know that you have broken your “never build same model twice” rule, but with the new Unimog wheels due to come out, do you think building another supercar-class hummer/humvee would be a good idea?

@Bullet for my Valentine

No, you can’t.

Very cool car, Sariel.

Can i have the building instruction?

@Ben

The slippage happens to my old Technic wheels, too – it seems that the spongy tyre just loses flexibility through time and reduces friction to the rim. If you usually don’t need rims alone, try gluing the rims to the tyres with a drop of glue at two opposite points. Worked fine for me.

@DoKnEs

Cały czas staram się zrobić prostą trialówkę, tylko z ładną budą. Skrzyni biegów jako odstępstwa od prostoty nie liczę, bo sprawdziła się na rajdzie.

Humvee był moim zdaniem najładniejszym samochodem na 1 rajdzie , tylko szkoda że cie zawiódł , na żywo prezentuje się pięknie .

Czy nie myślałeś nad zbudowaniem prostej niezawodnej trialówki ?

@Ben

Well, they just didn’t. Perhaps your tires are worn or something.

Hi

How come the wheel rims didn’t slip inside the tyres? i have some of those wheels and they are constantly slipping!

@Sariel well watching F1 I have the feeling that that ina curve the outer wheel is turned more, opposite to A. geometry, but it might be an optical illusion 🙂 I’m sure you’ve seen Mercedes cars with wheels turned to the max steering lock, and the inner wheel is bending outward while the outer bends inward. Basically this is the same with every car, but you can see it well on Mercs because due to lack of a drive axle the front wheels can be turned at a very big angle. Look at a Porsche Cayenne thought that’s an SUV, and 4 wheel drive, but yocan even see the spring/shock/air spring behind the wheel is set to bend backward, for some reason. Tricky thing this is, steering geometry… 🙂

@Mike

It’s certainly not easy and even messed up quite a bit, which is why I keep seeing sport cars with their front wheels set at some really weird angles 😉

@Sariel that must be true, backlash adds up… 🙁 I wasn’t only talking about the A. geometry, basically if you take any car, you’ll find no 90 degrees angle; the pivot point of their steering is not exactly vertical, it bends “inwards” and to the back, wheels themselves aren’t vertical, and they run towards each other, this all adds up to the geometry that makes cars run safe and stable. A. geometry is not particularly hard to use, I know you used it several times, but the rest.. that’s not easy 🙂

@Mike

You’re talking about Ackermann steering geometry, which I know well. But I don’t think that’s the case here. The problem is more likely the fact that this suspension consists of plenty small pieces put together rather that of few large specialized ones, and with the high tensions present in the Truck Trial, there is a significant backlash between these small pieces. I think it simply lacks the structural stiffness to hold the wheels against tensions.

@Sariel i real life cars wheels “run together” a bit, they are not parallel to each other, and other geometric angles are used, and the reason is, to minimize the wear on tyrres, provide return to center steering, etc. So I guess the reason why they bend is because you can’t really provide such a setup with Lego pieces, though there are experiments 🙂

With a car I had made I had a similar problem, it wasn’t heavy (it was only a chassis), it had a custom indep front suspension similar to the one you used, but simpler (no drive). The wheels housed much of the hub, but still as the car rolled forward, the wheels started to bend and lose their parallel setup. It’s the lack of real-life suspension geomety, I think. There’s a lot more to that than Ackermann geometry, and these are very hard if not impossible to reproduce with Lego.

@Tanner T.

Nope, I’m not planning to take more photos. The weight distribution is fairly equal, and the rear wheels are very similar in construction to the front ones. Also, it would have to be heavily modified to use different wheels, as these are the only wheels that can partially house the wheel hub inside.

The only thing that I can think of that would bend the wheels like that would be weight, but it seems the distribution would put most at the back which would, if they were to bend, make the rear wheels bend. Maybe you should try putting different wheels on it. Would you post some photos of the suspension?

@will

Your score does not count. You don’t score in the race, you just drive for fun.

what does it mean to not be classified?

@louis0304

They were not classified. Just like my Humvee.

Thats quite sad, it performed actually very good.if you make instructions for the chassis,other people could improve it.and why were trucks at the race weighing less than 2 kilos?

@Sariel 🙂

@Mike

No, I don’t at the moment, but who knows what future brings?

@Sariel hmm, the BMR should be effective.. especially if you can get some of the new cv-joint connectors, and avoid using u-joints.

Are you planning to develop (if it can be developd further) and use the suspension of the Humvee later on?

@claudio forlani

No.

do the instructions for this machine?

epicness achieved, i like the suspension a lot (no pendular anymore :D)

I agree for the tests at home, but do is not race with a model performance

is a suicide. I am convinced, however, that is a good model for the home

@GuiliuG

Testing at home and driving outdoors are very different. It’s very common to see a vehicle that performed well at home perform very badly in the real race.

It looks beautiful and the suspension is an uncommon one in lego truck trial ! As all the TT you made, i don’t understand why you don’t test the vehicule during one or two houres at home to test if it works good ! It would prevent bad surprises 🙂

first of all let me apologize for my poor English, are Italian.

I would add that I think some frames with tie should not be made because it is always a “game”. perhaps more simple frame like the jeep wrangler automatic transmission would be the best. I apologize if I said an idiot.

thanks.

@louis0304

Yes, I don’t.

Your best looking Truck so far! You don´t make instructions because the drivetrain failed,do you?

WOW awesome creation, my jaw hit the floor. It looks really good in black very good job.

simply AWESOME as all your creations. for me you are the best lego builder in the world =D

@Mike

I think the hard tyres were rather an advantage. However, the BMR will be using the 94.8 mm balloon ones.

@Sariel

ok 🙂 I don’t know much about this HD stuff, but the photos are very nice. I really think you gained useful experince with this vehicle. With the gearbox, a stable suspension (doubled 6L links on each side of wheel hubs for the BMR) you’re gonna be good!

did I see it right that you were suffering from spin outs due to the hard tyres? Apart from that and the drivetrain damage the Humvee was doing good. I saw that a truck might be very good but with poor weight distribution you suck.. like that white 6-wheeler with blue stripes. This Humvee is good because you have the whells at the ends of the vehicle, thus it is more stable.

@Mike

The photos are standard, no HDR used, except that I started publishing them 1200px wide rather than 800px wide recently.

As much as I trashed your video, I gotta say this is a fantastic vehicle. It was a brave thing to move away from the well-tested pendular suspension dsign. Maybe the bending occured because of the flexibility of the pieces used for the suspensiopn added up; I see the pivot point fot the 6L steering links were quite far (some 3-4 studs?) away from the wheels’ turnng point, that might add to it. But this is the way you can build such a suspension.. all in all, even though you were not classified to race this is a huge improvement! 🙂

oh and photos do look very nice 🙂 are they HD? 🙂

@Nico71

There are two vertical 5L beams at each wheel, bracing the structure from two sides.

Nice ! The suspensions system is interesting, spite of the strenght. Maybe with adding a 5L beam verticaly to lock the structure ? Also, too bad that your TT has not a fake engine, for me this is a incontrovertible point. Maybe for the next one 🙂