Caterpillar 385C Front Shovel Excavator

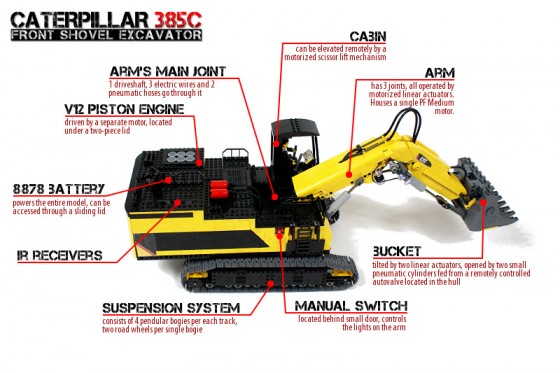

Large model of a Caterpillar front shovel excavator designed for a public display. Features a drivetrain with a subtractor, superstructure rotation mechanism, V12 piston engine, arm with 3 joints controlled remotely by motorized linear actuators, pneumatically opened bucket, remotely elevated operator’s cabin, lights and custom stickers.

Datasheet:

Completion date: 11/06/2010

Power: electric (Power Functions) / pneumatic (fed from internal compressor)

Dimensions (with the arm in ‘resting’ position): length 80 studs / width 28 studs / height 35 studs

Weight: 3.5 kg

Suspension: pendular bogies

Propulsion: PF XL motor geared down 9:1, through a subtractor

Motors: 2 x PF XL, 6 x PF Medium, 1 x 71427

I wanted to build a front shovel excavator controlled by linear actuators for some time already. It took me a while to find a machine with a distinctive silhouette (as many large front shovel excavators are shaped similarly) and my choice was the Caterpillar 90-tonne machine with an unusual cabin elevation system.

The model would be built at much later time if it wasn’t for the people from the Focus popular science magazine, who invited me over to a Picnic of Science held in Warsaw (the largest popular science event in whole Europe). It was a kind invitation, but it also meant a fixed term to build something spectacular and, so to say, public-proof. I had to hurry to make it on time, I even used my absence of leave to finish the model, but I felt it was still not tested sufficiently.

The look of the model is accurate to some degree. The size and all the dimensions are kept faithful, and the colour theme is an exact rendition of one of the two Caterpillar liveries I’ve seen this machine with. The details on the top of the model, however, were intended to look diverse rather than accurate, the V12 piston engine model is completely unrealistic (but it turned out to be a great crowd pleaser, as anticipated), and the arm lacks a single actuator. Additionally, the way the bucket opens up has been changed slightly to make the bucket look better and be more structurally sound.

As for the functional side, it was largely affected by the unexpectedly huge weight of the model. While the chassis was providently built around a really massive studless frame, the drivetrain had to be additionally geared down to handle it. Even with the 9:1 gear reduction, some gears in the subtractor are still being grinded to dust. Not a single gear in the drivetrain was broken, but there was a plastic dust coming out whenever I opened up the subtractor. But in fact, the painfully low speed of the model is accurate as the real machine moves at 4.4 kmph.

There is a studless Technic turntable between the chassis and the superstructure. The stability is provided by four double rollers, consisting of two wedge belt wheels with rubber tires each, and integrated into the superstructure’s bearing frame (located, as usual, in its ‘floor’). The rollers are supported by large tiles on the top of the chassis. I have assumed that use of large rollers will be a convenient way of filling the gap between the superstructure and the chassis, and that the rubber tires will provide a degree of elasticity should the superstructure tilt while operating. Whether these assumptions were accurate or not is difficult to prove eventually. But I was right to only use four sets of rollers (front/rear/left/right one) as they provided sufficient stability for as long as they were part of a sound, rigid structure.

The major drawback of this model is the use of an 8-teeth gear wheel as the final part of the superstructure rotation mechanism. The weight of the superstructure coupled with the friction generated by the rollers’ rubber tires caused this gear to be severely damaged during final tests. Since it was very difficult to replace (read: it required to take half of the model apart) and there was no guarantee that the new gear wheel wouldn’t share its fate, I left if the way it was. Which means that the superstructure rotation works only when aided by hand. The video clearly shows that superstructure rotates as long as the rear part of the hull is being gently pushed (at some point I even use a single finger for that to demonstrate that there is indeed a mechanism working there and that I’m not simply rotating the superstructure by a hand). The use of the 8-teeth gear wheel, which worked fine in lighter models, was a mistake here to begin with. I should have used a worm gear instead, preferably one that would be mounted to the chassis and driven from the chassis.

The rear part of the hull houses the 8878 rechargeable battery which powers the whole model and which can be accessed by a small sliding lid. On its left, there is a big V12 piston engine driven by a separate PF Medium motor coupled with the drive motor (which means that there is no mechanical connection between this engine and the drivetrain whatsoever). The whole V12 is fully enclosed inside the hull, and can be displayed by opening up a two-piece lid. I always wanted to include a piston engine into an excavator model, and with a model that large I finally did. On the right side of the battery, there are four IR receivers and beneath them, there is a pneumatic autovalve which controls the opening/closing of the bucket.

The front part of the hull houses a massive frame around the arm’s main joint. The arm is 6 studs wide at this point, and there is a driveshaft, two pneumatic hoses and three electric wires going through the joint. On the right side of the arm there is a PF XL motor which drives two linear actuators that lift arm’s first section. There is also a PF switch which controls the lights on the arm, and which can be accessed by the means of a small door in the right side of the hull. On the left side, there is a cabin sitting on a scissor lift mechanism, which is moved by a single linear actuator driven by a 71427 motor located under the piston engine. The elevation range of the cabin is impressive, especially when you realize that the whole scissor lift mechanism is just 3 studs tall. The mechanism has its drawback too – it puts a very high load on the motor, so it has to be additionally geared down (hence the low speed of cabin elevating) and the weight of the cabin has to be kept low (hence the number of details is lower than intended).

The arm consists of two sections. The first one is controlled by the aforementioned PF XL motor which drives two linear actuators integrated into the front part of the superstructure’s frame. The second section is controlled by a PF Medium motor located in the hull, between the arm and the 8878 battery, which drives a single linear actuator integrated directly into the arm’s first section. There is another PF Medium motor inside the first section, which drives another two linear actuators that tilt the bucket. The second section of the arm is pretty much empty. The arm was built in the same way as it was with my previous excavator: it consists of a studless frame with directly attached actuators, and a studfull outer skin which provides extra stiffness but is not necessary for the arm to work. I am not quite pleased with the somewhat weird look of the pneumatic hoses on the arm – I could have enclosed these inside the arm, but I felt that an excavator’s arm ought to have some hoses on it. But due to the complex construction of the arm’s first section, there was no way to arrange the hoses in a more realistic manner.

The arm has some excellent movement range. In fact, it is somewhat better than that of the original machine – to the point at which it is not necessary to open the bucket to unload it, as it can be simply tilted.

As for the bucket opening mechanism, it is very simple and consists of just two small pneumatic cylinders. Some minor part of the load is usually left inside the bucket when it opens, but this is caused by the bucket’s inner shape which results from its internal studless frame rather than by the mechanism itself.

This has doubtlessly seen more practical use than any of my other excavators, as it was operated for a couple of hours straight during a public event. It has also successfully faced the devastating curiosity of little children present at the event, but I won’t describe the details lest I sound like a contraception promoter 😉 In fact, the failing superstructure rotation mechanism is the only thing that prevents me from calling it my best working excavator model ever. The model has been also highly acclaimed by LUGPol members – so highly, in fact, that I was genuinely surprised.

Photos:

Work in progress photos:

Video:

Media reference:

Hobby Media (Italian only)

@Corm01

Not really.

Hi can people commission you to build stuff and would you ever sell this

@Pedro

Just a regular paper, then I put a transparent Scotch tape on it.

How do you made those custom stickers?

What kind of papel did you use?

Thanks!

@Cars2cool

Here you go: http://www.dafont.com/

where do you find all the amazing fonts you use in your pictures?

@Gimba96

http://www.bricklink.com/catalogItem.asp?P=6573

What is the part number of the differentials used in the substractor? I mean the ones with 4 bevel gears inside it?

@Sariel

ok thanks

@oren90

It’s clear now, but I don’t think the matter of stability depends entirely on the weight ratio. There are other factors to consider, such as the width and length of the tracks or the height of entire model. Since the weight of the superstructure is directly ‘laid’ on the chassis, I don’t find the weight of the chassis alone to be a significant factor.

@Sariel

the point of my question is and sorry that it wasn’t very clear what will be a good weight ratio between the base and the body of the excavator assuming you’ll end up with a total weight of around ~3.5 kg as i’ve that most of your excavators end up weighing around that weight, where will you try to focus most of the wheight so that the model will be well balanced and won’t tip over or won’t be very stable?

sorry in advance if this is still unclear

@oren90

Of course there are huge differences because there are various ways to build the chassis. You can put drive motors in the chassis or in the superstructure, you can put superstructure rotation motor in the chassis or in the superstructure, you can use more or less details in the chassis, and so on. Frankly, I miss the point of your question from the very beginning.

@Sariel

do you have an average by any chance like for example around ~1kg or ~2kg or does it vary between models in huge differences?

@oren90

It’s different for every model.

how much does the base usually weigh in these models?

@Sean

Then you haven’t looked well enough: http://sariel.pl/2009/03/compressors/

I see in the specs it has an on board air supply “pneumatic (fed from internal compressor)” I looked around your site a little but couldn’t find any details do you have any other information on how you built that? Thanks

@nate

No. You would know if you read the FAQ.

are you willing to sell any of your models?

Listen, real excavators ARE slow. And I wanted to have accurate steering, which would be impossible with direct drive & speed control.

Wouldn’t it be better to use direct drive with gear adduction

The song is “Hocus Pocus” performed by Helloween.

Hey Sariel!

Great construction, nice to know about somebody like You!

I track Your website for a couple of months and with any time I visit it, i wonder about returning to Lego 🙂 There is a blue-box still in my wardrobe 😛

Could You let me know about the song in the second part of the video (with a kind of yodeln)?

Greets!

Sapacz

PS. I’m Polish, but more comments are in English – so I wrote too 🙂

Yes, thanks.

I check another of your brilliant machines.!

The subtractor is shown in the Ideas category if that’s what you mean.

On the second picture you can not see the design in order to get it to steer!

How can i build the cool steering

Hi like pretty much aesthetics and proportions here. I actually like in particular the arm, the colors and its smooth movements. Major drawback of course the superstructure rotation mechanism.

Rough estimate would be below 1 kg, I guess. The model uses 8878 battery, so there are no really heavy PF components.

@ Sariel

And it (the big bucket wheel excav) didn’t have motors in it yet, did it?

Out of the 3,5 kilos, how much does the pf stuff, motors, wires, battery weigh? just a rough estimate

No, this is not the heaviest. My big bucket wheel excavator was cancelled at roughly 7 kg.

about the curious children… good thing none of them dropped the model, it could’ve broken someone’s foot… 🙂 3,5 kgs, Jesus. Is this your heaviest model so far? Or were the mobile cranes heavier?

Never seen so good looking “MOC” !

Yet another great MOC from You!

Well, I based the model on a blueprint from the Caterpillar’s official website. I didn’t much rely on the photos.

Great model, great proportion on the superstructure but if you have been based on this model : http://www.degand-terrassement.com/media/catalogue/385FS.jpg You pneumatic arm hasn’t the right proportions, too long, not enought looks heavy. Can you explain me this choice ? Anyway, when I have seen the cab lift up, I was very surprised (I haven’t expected). 🙂

No, I don’t.

the instruction for ensambling this models you sell?

i´m in spain and congratulations for your job

The bevel gears inside the differentials, yes. I packed 4 of them inside each differential and added some half-bushes to make them sit tight. They didn’t snap or break, but they produce a lot of plastic dust.

Great job, amazing how you put so many features into a limited space. The bevel gears were the weak links in the subtractor, right?

Awesome! I like the V12 inside the hull.

Shame the 8 teeth gear broke.

your best excavtor yet, love how all the stuff in the arm in inclosed 🙂

Hey man!nice creation.It looks awsome!wish that super structure can rotate by itself though.im still waiting for that pf arm.But don’t make a whole lot of them to make a terminator army or else world war III will brake loose.