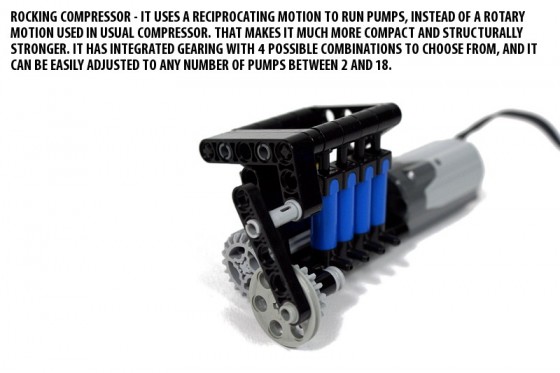

Rocking Compressor

New compressor design, using reciprocating motion instead of a rotary one. Smaller, stronger and more adjustable than traditional compressors, it can run up to 18 pumps.

I have presented some ideas for compressors earlier – they used at least two sets of alternatingly working pumps to keep the airflow fluent and the vibrations minimal. The problem, however, was that they all used a rotary motion to run the pumps, which made them large and structurally weak (e.g. because no central axle could be used to run the pumps, there had to be an empty space for the pumps to move). Both these problems increase rapidly with the growing number of pumps.

Having recently bought an extra supply of pumps, I was looking for a solution that would result in a compact and strong compressor. I have found it by replacing the traditional rotary motion by a reciprocating one. The compressor I’ve developed can use any even number of pumps between 2 and 18 (this limits results from the 12-studs long axle being the longest one we can use to put the pumps on), while being much smaller and stronger that the traditional ones. It can work with any motor, and has integrated gearing that can be adjusted to your needs by picking one of 4 available combinations. The only tradeoff is the fact that it generates more vibrations that the rotary compressors, but it still makes it a useful alternative. Even with 18 pumps, this compressor is only 14 studs long (not including the motor). The exemplary variant I’ve built for the video uses 8 pumps and its dimensions are just 9x6x7 studs (again, not including the motor).

You can find a complete instruction below, and the video is pretty explanatory. While many people tend to choose large compressor based on RC motors for large models, I dislike this solution because RC motors are noisy and difficult to use with the Power Functions system (they run at a current so high that it makes the battery boxes and batteries go off). Therefore for me, this solution will be a much better alternative in the future.

@Roi Neustadt

I don’t know the weight, I don’t know how much PSI can it produce, I haven’t tested any compressors this way.

I would be extremely grateful, if you could let me know the weight of the structure above, in a configuration (number of pumps) that outputs more than 12 PSI constant, is this here above, the lightest weight LEGO pumps structure or have you developed lighter ones in terms of weight? Thanks!@Sariel

@Roi Neustadt

No idea, I have no experience with DC motors.

Hello!

I am totally unfamiliar with LEGO – but i am looking for a way to be able to create 12-20 PSI, using a micro compressor and a micro DC motor, that weigh together, no more than 25 grams.

Do you think it is possible to achieve, using the LEGO pneumatic valves and some kind of engineered structure, as the one in this page or other LEGO structures?

Thanks!

@powerstrokintx

That’s not really matter of the pulley, that’s the matter of what motor you use and how tight you make the rubber band sit on pulleys.

Lets say if I wanted to use this with a pulley system, will the rocking compressor with just 2 pumps need a larger pulley to power it.

Or can a smaller over driven pulley work?

@william

It doesn’t “have” pressure. You drive it faster – it pumps more air, simple. No, I can’t make it for the manual pump.

how much pressure does it have?

and can you make one for the hand pump?

its all right i dont care 🙂

@josh

Ok, sorry, I shouldn’t be rude.

ya i guess i do dont i

@josh

Oh, so you know it after all?

like bricklink

@josh

Just where you buy all the other Lego pieces.

Where can u buy th blue compressor things????????

After getting some additional items I was able to build this compressor with 4 bumps. In near future I’ll try to build it into the 8455.

One thing I didn’t read out is the question whether I should use clutch gear or not due to the fact that the bumps and motor will slow down when the tubes are full of air.

Any help and tips are highly appreciated.

And thanks Sarile for brilliant work 🙂

@charles

Roughly 40 psi.

what is the max presure lego can handle?

acording to my calculations (and Techbricks tutorial) this with 24t to 12t gears (ratio 1:2) and 18 pumps will pump 5231.2 cm3 of air / minute (if the m-motor handles the torque) which results in enough air for almost 1412 in-and-outs of a big cylinder / minute

@matthew

I wouldn’t use the large pump. It has a strong spring and may cause damage to parts or to the motor.

I have tried attaching a hand pump to a 40 teeth gear.I used a RC buggy motor which is both fast and strong.Is it a good idea to do this?

@Stephen

Yes. Autovalve works with any compressor.

Would this pump be a good design to use with your Auto-valve, lets say inside an excavator?

@Jams

Please note that this compressor is intended to be built into something, not to work as a stand-alone module, therefore its structural integrity is not an issue. When I use compressors in models, I tend to attach them to the model’s frame firm & tight. Space is always an issue, and rotary compressors need a lot of it if you want to use more than 4 pumps at once. You’re right about the vibrations – certainly an issue.

As well I’m sure vibration is going to be a big problem once implemented, as opposed to a rotary compressor which does not see any extremes in terms of limited movement like this

This does not look structurally stronger at all, I’ve never had problems with fitting rotary compressors into tight spaces, nor have they ever been flimsy and weak. Though, the more I read your article, the more I see that you are referring to set ups with many many many mini pumps, which begs the question, if you’re looking to build an 8 pump compressor, is space really an issue??

Its a brilliant idea though, I think it just needs much more reinforcement where the gears are at the front, but that is best saved for a real implementation of the device

@Sariel

I use the for in my swimming pool beacause i reinforce the top and I use the for a under-water platform that need huge quantities to rise

@Ramacco

Colour doesn’t matter.

Is the yellow pump necessary? Or can you also use a blue one? Ramacco

@Sariel

Thank you for answering. Ramacco

@Ramacco

You don’t need an airtank for autovalve, in fact to use an airtank would be completely against the whole idea of an autovalve.

Hi Sariel,

If you use a AutoValve, do you also need a Pneumatic Airtank or not?

Or is this compressor enough?

R,

Ramacco

Silnik RC i dwie pompki, rozumiem, że o te małe chodzi, dzięki.

@NaturalBornUser

Polecam silnik RC + dwie pompki. Daje się upchnąć w niewielkiej przestrzeni i jest wydajne, tylko głośne.

Jeśli tak mówisz. Nieiwle kompresorów jak na razie budowałem. A teraz zależy mi głownie na małych rozmiarach i szybkości sprężania.

@NaturalBornUser

Dzięki, ale nie jestem przekonany czy bardziej nie opłaci Ci się kompresor na silniku RC. Prędkość wyjściowa takiego silnika daje naprawdę dużą wydajność z bardzo prostego kompresora.

Bardzo udany kompresor, zasięgnę prawdopodobnie tego pomysłu przy kolejnej koparce.

@RjbsNXT

No, that would be 58, my bad. Anyway, crazy number.

@Sariel

With 32L axles, wouldn’t it be 60 pumps rather than 48?

@WillisDee

16-studs long axles are elastic and won’t hold the pumps in place. There are even 32-studs long axles if you care, but who would need a compressor with 48 pumps?

I found some 16L axles on brickink you could fit a few more pumps in with those

awesome idea! you could use the same principle for a pneumatic engine

cool idea. i wonder how a compressor like one of these would affect the performance of the volvo.

Fabulous design, but I think when higher pressure is needed that the rocking mechanism will need to be strengthened.