2-speed Automatic Gearbox

My first automatic gearbox, based on a design by Misha van Beek, but improved and simplified.

I always liked the idea of incorporating automatic gearboxes into large models, unfortunaltely such gearbox designs are unique and I only know two by Misha van Beek. While both are advanced and show great knowledge of the author, they are also large, complex and none changes gears smoothly. I thought that the new, small differential may give me a good opportunity to create a more useable design. I had three simple goals: to make a gearbox that is small, simple and above all capable of changing gears without jamming. The two first were easy, the third one took some time to work out, but eventually I got exactly what I wanted.

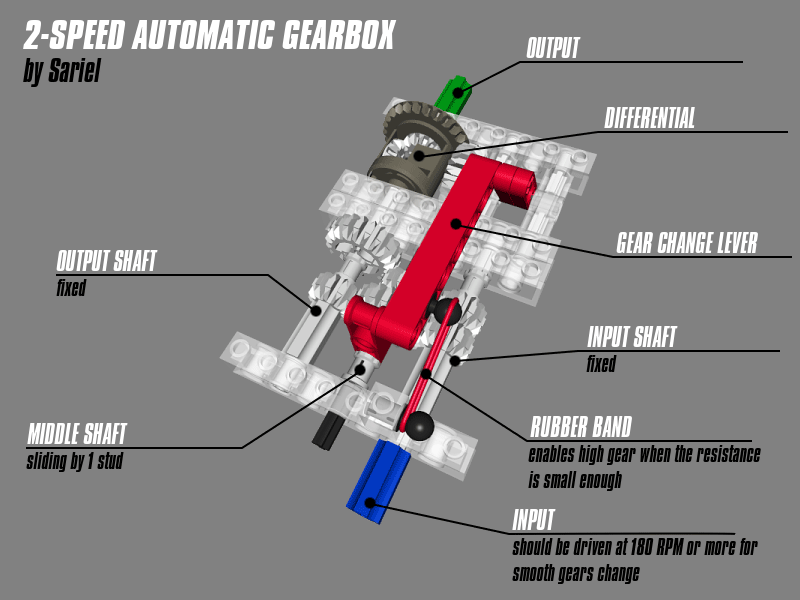

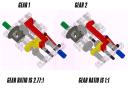

The basic idea of Misha’s design is to use a differential to transmit the drive in such a way, that if the resistance of the output grows, it will at certain point trigger the gearbox to switch to lower gear. Thus the motor will have a better chance to overcome the resistance, and once it’s done the gearbox will switch back to the higher gear. Whereas Misha has taken this idea further, and created gearboxes with more than just 2 speeds or with no fixed gear ratio at all, I considered two smoothly operating speeds a better option than three or more jamming ones. The lower gear has 2.77:1 gear ratio, and the higher one has 1:1 gear ratio. I have been experimenting with more different ratios, but as the difference increased so did the tendency to jam while changing gears. The 2.77:1 ratio difference should be sufficient in most cases, and it offers a reasonably smooth functioning of the gear change mechanism.

The construction of the gearbox is really simple. It fits into a 8×12 studs rectangle (plus the middle shaft protrudes out by 1 stud on higher gear), and axles of any length can be put into input and output without taking the gearbox apart. Moreover, the horizontal liftarm which servers as the gear change lever, provides a lot of space to adjust the tension of the rubber band accordingly to the weight the gearbox is supposed to handle (namely, the towballs it sits between can be put closer or further from each other).

You can see the smooth functioning of the gearbox in the video. I have also provided a parts list (just 45), an LDR model of the gearbox at lower gear and higher gear, plus an exact instruction which can be found below.

@Alexander

Then you have to find another way without using this gearbox, because it won’t work. Perhaps you’re spending to much time writing here and too little working on your model?

I need a two speed gearbox, for my tracked viercle but don’t have any space left on the remote.

@Alexander

Forget about using this gearbox in a serious crawler.

I’m making a crawler tracked viercle using the speed control remote and powered by a few pf xl motors. can I make the differential on one drive to change both the drives gear or would it go wrong on a tight turn?

@Alexander

Yes, you can use spur cogs, and you’ll need a custom differential to handle more torque.

just realized it uses bevel cogs. can i change them for normal cogs(except on the differential)

is there a way to increase the torque it can handle? would a custom differential or aligning a few more bevel ones increase the torque it can handle? also if I gear up the xl motor with a 40 tooth cog to an 8 tooth one could it handle the torque?

It seems like the backlash between gears made driving the differential while switching gear ratio possible.

@ron

Maybe. Try it.

What about the L motor?

@ron

I don’t think this gearbox has any chance of handling the XL motor’s power.

Hi Sariel!

I plan to make some vehicle incorporating this gearbox, its just the thing I need. However, I have some doubts to settle. If I use a PF XL motor, I would have to increase the revs from 146 to over 180 before the transmission (simply by gearing up) but then after the gearbox I suspect that it will go to fast so would it work if I gear it down a little?

Keep up your great work!

@david

That would require serious changes to the whole design.

Can you swich the bevel differential with a non bevel differential

@Klaus

I don’t have a list, sorry.

hey, can you send a list of the part numbers ?

@Cody

No.

Could the differential be swapped for two or three gears?

Will use it, it’s what I was looking for, something small and reliable and easy to make.

It’s perfect.

@Muaddib

No, I don’t think it would have much sense. These are two separate mechanisms needed in different situations.

Hi Sariel,

really great work on your site.

Have you ever considered to combine the automatic gearbox with the limited slip differential?

Would it make sense? First it would be slowe down a gear and after that the differential will be locked.

Have a nice weekend.

Muaddib

I think you should go study to be constructor. You made real impressive models.