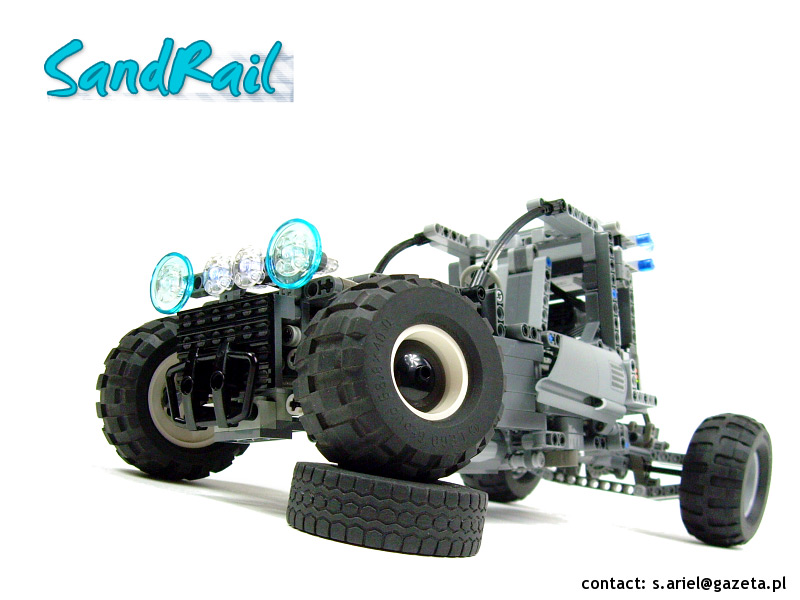

SandRail

A simple buggy. Features 2-speed remotely controlled gearbox, live rear axle and lights.

Datasheet:

Completion date: 23/11/2008

Power: electric (Power Functions)

Dimensions: length 47 studs / width 25 studs / height 25 studs

Weight: 1.08 kg

Suspension: front: independent with shock absorbers / rear: live axle on shock absorbers

Motors: 2 x PF Medium

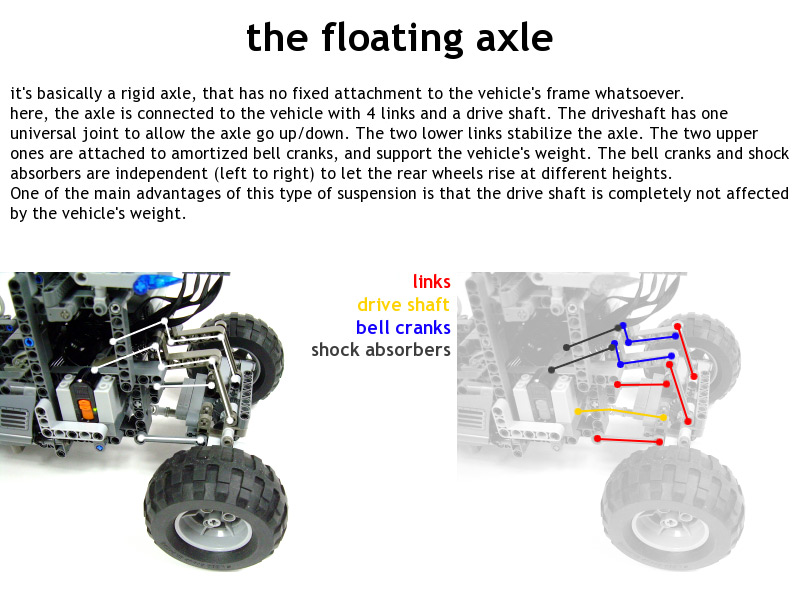

A simple sandrail (subcategory of buggies), built basically to test my live axle concept. A live axle is an axle that has no fixed attachment to the frame of the vehicle. Instead, it is connected by a system of links and supported by shock absorbers. Live axle suspensions are usually complex, but offer very good stability and excellent performance, comparable to those of a typical independent suspension. And just like the independent suspension, live axle does not let the vehicle’s weight affect the drivetrain, which means that it performs better in heavy vehicles that the pendular suspension does, because the weight doesn’t generate extra friction on the drivetrain components (except wheels, of course).

In Lego, a very complex live axle systems exist, with probably the most extreme example available here. Therefore my goal was rather to create something as simple as possible. I ended up with an axle suspended on 4 links and a driveshaft only – a solution that turned out to blend simplicity with reliability pretty well. It had two minor drawbacks: it was slightly affected by the driveshaft’s torque, just like the pendular suspensions are, and the driveshaft could be theoretically affected by the vehicle’s weight to some extent while maing a turn or climbing certain obstacles. Despite that, this suspension system worked far better that I could expect.

Another noteable feature was the use of the direction sensitive gearbox I have developed earlier. It was braced by liftarms here, and allowed the vehicle to be driven only forwards. It did work as expected, but the liftarmic frame turned out to be somewhat loose, and did not deliver the kind of performance that traditional bricks could.

The model was built with minimal attention to the aesthetic side, I just wanted it to look realistic, not pretty. Therefore I’ve used rather unusual palette of colours, and did not intend to film the vehicle. The LUGPol community, however, showed much interest in the suspension concept, and persuaded me into filming it, so I’ve eventually published a video titled Live Axle, to emphasize the fact that it was the suspension concept that was important, not the actual car.

@TwentyLeggedHen

Yeah, probably.

Just wondering, why did you choose dark grey instead of dark bley for the rear axle? Was it because of the color of the shock absorbers?

@Eric

You can easily build it from photos.

do you have instructions because i want the rear axle???

@Sariel

Thankyou, this was a great help

@liamisamonster

These are dark grey short shock absorbers. They have nothing to do with the Offroader set, and they are of medium stiffness when it comes to shock absorbers. Light grey ones are softer, yellow ones are harder.

are the shock absorbers the same strength as the ones from the 8297 (offroader) or are they the weaker ones from smaller sets(light grey colour)? It seems a bit difficult to determine because of there colour appearing brownish and unfamiliar. It will help alot because i would like to replicate this design in some way and i am unsure whether my shock absorbers will support the model’s arsenal of power functions etc.

@Patrick

Adding it is possible but will change nothing. The lateral movement is avoided thanks to how the driveshaft is constructed.

Is it beneficial (or even possible at this scale) to add a watt’s linkage or panhard rod? how is lateral movement avoided without such a linkage?

@Sariel ok thanks

@liamisamonster

There was just no place to put it lower.

was the battery box put so high on the back for a reason? or is that just a design feature, and well done for simplifying it so well.

i can try

@allu

Did you try to make a steered axle and suspend it like the live axle? It’s really that simple.

I can make a live axle but I don’t know how to make a steered live axle

I didn’t find a steered live axle

@allu

There are plenty of steered suspensions in the Ideas category, check it.

I’m working on a monster truck and I need help on the steering

how to make it steered I’m working on a monster truck and I need help

@allu

Yes.

could you mace it steered

well i wish u guys with all ur talent would give us that arnt build ur stuff as well this would be an awesome build ,,,

@will

No, because absorbers can’t tilt sideways.

would it work if i replaced the upper pair of links with shock absorbers

@Sariel

Thank you.

@DW

Well, if a single M motor drives it, I think you should try something between 3:1 gear reduction and 1:1 ratio. Fresh batteries will help too, of course.

@Sariel

The Buggy is rear wheel drive. It is powered by 2 M Motors, one for steering one for driving. The wheels are “http://www.bricklink.com/catalogItem.asp?P=41896c03”.

@DW

I have no idea. I don’t know what motor drives it and what size are the drive wheels.

I have made a dune buggy but I don’t know what is better for It, to have off-road capabilities or only speeding. and If it is off-road what gearing should I use. Weight=700 grams.

Yes, they are the same length.

also are all the links the same length and when are you going to build the monster truck

81.6 x 38 R wheels.

what size wheels did you use on the rear axle

@sqiddster

This suspension doesn’t allow that kind of angles on the u-joint.

Hey, very nice suspension there!

Does the single universal joint usage produce problems? As i’m sure you know, they tend to provide increasingly discontinuous (is that the right word?) motion as their angle increases. Do you notice any ‘jerk’ in the speed?

Many thanks, sqiddster

@Lukas

The clutch gear slips under a very specific torque. If you want it to slip less, place it close to the motor and put the gear reduction behind it. If you want it to slip more, place it further from the motor and closer to the final output. The trick is simply to manipulate the torque this gear transfers with some gear reduction before or after it. Check the Gears Tutorial if you have problems.

@Sariel

So you suggest moving the clutch at the end of the whole gear box, instead of at the beginning, right behind the motor?

@Lukas

The 3rd motor was supposed to control PF switch on the drive motor, but was not used eventually. There is no clutch in the drivetrain. You can’t make a clutch gear slip less, but you can put an extra gear reduction before it.

You wrote you used 2 medium motors, but in pics you can see 3rd one mounted on top underneath the batter box. What is it for? Also question #2: did you use a clutch gear on driver motor? Is there any tutorial about clutch gear? How to make it slip less (transfer more torque)?

@Lukas

Ciekawe, nie miałem pojęcia.

@Jerzy

tylna os jest skretna i sterowana niezaleznie od przednich kol, poprzez joystick w kabinie kierowcy. Pozwala to na ciasniejsze nawrotki.

Jak to nie widziałeś? Ciągle widuję jakiegoś monster trucka i zauważam że tylna oś (przy tych tak zwanych driftach,w koło) się skręca,ale to również może wynikać z tego że swoją masą tylne koła się lekko skręcają.

@Jerzy

Hmmm jeszcze nie widziałem monster trucka z obiema osiami skrętnymi.

tylko spróbuj zrobić tak,aby mu dwie osie skręcały

@Jerzy

A to czas pokaże, na szczęście koła już mam 🙂

no no ładne zawieszenie,ale czy zdołasz zrobić monster trucka?

@crawlerdude

I have specifically listed where I buy the parts from in the FAQ. Why don’t you read it?

@LEGO101

We have Trials in Poland, Czech Republic and I think France and Netherlands too. I know nothing about Trials is US.

where are the truck trials held?

are there any in america?

i cant find any of these parts on pick a brick, do you just collect them from sets or do you get them at some other website?

@crawlerdude

Don’t you think I would mention it if I used one? You can really answer your own question if you just think about it for a sec.

I am extremely sorry for all my questions, but did you use the return to center steering mechanism for this buggy?

@crawlerdude

Listen. You can easily measure the links yourself or from googled images. And you can easily see the type of the shock absorber used on the photos, unless it’s too difficult for you to look at these. I can’t possibly imagine any simplier explanation on how the floating axle works. You just have to read it. I’m really tired of all your questions that can be answered by simply READING or LOOKING at what’s in front of your eyes or by using the Google for like 5 seconds.

sorry for all the questions but did you use a hard, soft, or normal spring shock absorber

one more question, do you know the measurement of the links?