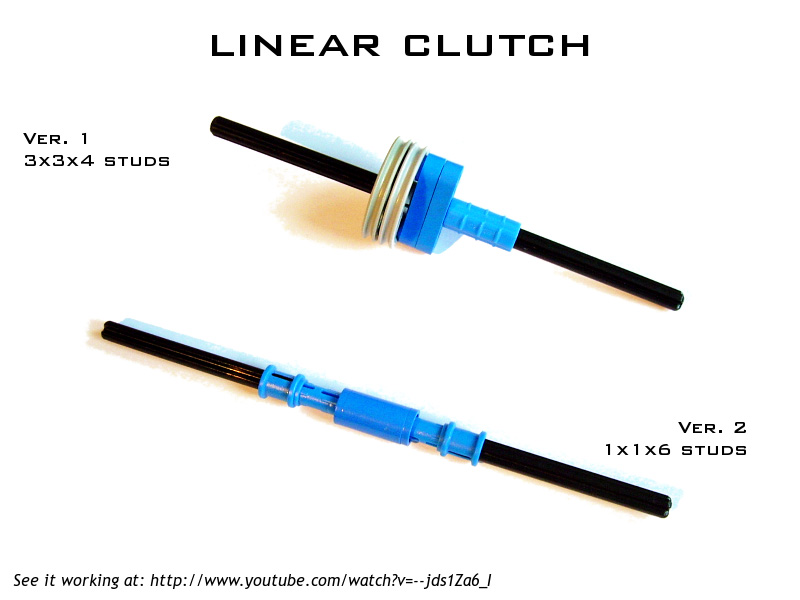

Linear Clutch

Two types of clutch that can be used on a single axle.

Using clutches with LEGO parts is usually a bit troublesome. The basic idea of a clutch is that it starts to slip rather than rotate when a certain torque is applied. A dedicated LEGO part exists in form of a 24-teeth gear with an internal clutch, as well as an alternative solution that involves using rubber bands for transmission. Both these solutions have one common drawback: they require parallel axles located next to each other. It it not possible to install them directly on axles located in a single line. Having a need for such a possibility, I have developed two simple clutches: one with dimensions 4x3x3 studs, and the other one with dimensions 6x1x1 stud. The resistance of the first clutch can be slightly adjusted by using axle pin with or without friction. Instructions for both versions are provided below.

Hey Sariel, I liked this, and came up with a few of my own, using the 3L axle with a stud on the end.

Both designs will hold together, are no larger than 3L in diameter, and (although I have not tested it, I’m on vacation at the moment) should provide more friction than these.

http://www.brickshelf.com/cgi-bin/gallery.cgi?i=5716945 (When public, I did just upload this)

Thanks!

He does. I saw your limited-slip differential there, too.

It is VERY likely to fall apart. Just tested it…

i had 2 of version 2 side by side, with a gear in the middle connected to the motor, and it acted as both a clutch and a differential. this was before the new differential pieces were available

Very useful ideas! Especially the 1x1x6 clutch which fits nicely in cramped areas.

Let me suggest one 2x2x3 variant: http://www.brickshelf.com/gallery/Legoism/Ideas/microclutch.jpg

Its slip torque is 4.5 Ncm ― at least with new parts. With older ones it is down to about 3 Ncm.

@Tdubs

I’m afraid this guy steals other people’s ideas.

I also saw this and your 4 speed gearbox at this website. http://www.brickshelf.com/cgi-bin/gallery.cgi?f=462910

@Marin

Interesting and quite compact.

I really admire and appreciate Your work, Paul. I’ve tried this clutch in an 8-wide PF truck I made (I’ll send You a link once it’s online if You’re interested) but on some ratios it was too weak and after some time of driving the truck (I used the clutch for the steering mechanism) it got worn out and made squeaking noise and didn’t work at all. So I came up with a different clutch (and it turns out it sustains more resistance) – http://img219.imageshack.us/img219/9126/clutch.jpg – (if You use the thicker bar (there are two types, not listed in BL catalog)).

it also works as a replacement fo differential

@Kowal

It’s possible, but these are separate mechanisms and they will not affect each other.

What about using this clutch with limited slip differential?