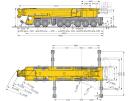

Mobile Crane 14x8x10

Big mobile crane, based on Liebherr LTM 1400. Features full suspension, 8 wheels drive, 10 wheels steering, 3-section telescopic boom with a 2-block situation indicator, star system outriggers and V8 piston engine. Built entirely in Technicfig scale.

Datasheet:

Completion date: 29/12/2007

Power: electric (Power Functions) / pneumatic (fed from internal electric compressor nad internal manual pump)

Dimensions: length 125 studs / width 22 studs / height 33 studs

Weight: approx. 5 kg

Suspension: full pendular without shock absorbers

Motors: 2 x PF XL, 2 x PF Medium, 1 x RC

Pneumatics: two circuits with internal electric compressor, and additional manual pump with an airtank

An ultimate result of a fascination by the mobile cranes. I have spent a lot of time since my previous crane was built, planning how to make the next one better. In the meantime I’ve finally bought the 8421 set, which has greatly influenced the project.

The boom was the first thing I’ve built. It consists of 3 sections, with the same extension mechanism by Jennifer Clark as in the last crane, using hybrid rack & pinion plus pulleys system. The boom weights approx. 1.2 kg and can be extended from 112 to 290 studs (approx. 2.3 meter). It is fully covered, with all the mechanics and ropes included inside. The third section of the boom includes the LED brick from Exo-Force sets, which turns on when the third and second section are squeezed together. This situation, when the boom is being retracted too far back, is called a 2-block situation, and the LED brick is intended to indicate when it’s about to happen. As the linear actuators were still unavailable at the time the crane was built, I have designed my own mechanic cylinder, which was huge and looked unrealistic, but proved able to lift and support the boom.

The carrier was the second thing to be built, and the most complex one. Most of the space inside is taken by the suspension, drivetrain and steering systems. There are basically three systems of axles: axles 1 & 2 are steered and driven, axles 3 & 4 are only driven, and axles 5, 6 & 7 are only steered. All axles have pendular suspension, most of them with transverse modules without shock absorbers. The crane is kept stable by axles 3 & 4 which use longitudinal modules. The steered axles obviously feature various steering ratio. The carrier is kept together by a complex frame, strong enough to let the crane be carried by a hand. The frame required a lot of planning, as it had to be as strong and compact as possible, as well as to be placed in the upper part of the carrier, as the space below was needed for suspension. Finally, the frame consists of a number of smaller modules joined using Technic Pins Long with Stop Bush, simply to make the assembly easier – it would be quite a bother to be forced to move the entire 1-meter long structure every time the access to its other side was needed. Front part of the carrier includes a PF battery box, a V8 piston engine, and a Technicfig-scale cab with a functional steering wheel. There is also simple amortized bed to support lowered boom – a solution present in the real Liebherr crane. In the middle of the carrier, there are 4 star-system outriggers that are deployed and lowered by two pneumatic circuits.

The superstructure is connected to the carrier by a regular Technic turntable of the newer type. It turned out to be a bad idea, as the turntable was unable to withstand the tensions generated by the elevated and extracted boom. The lack of space in the carrier forced me to locate an electric compressor in the superstructure. It was driven by an RC motor powered from the old-type battery box attached at the back of the superstructure, as a counterbalance. Since the compressor had low efficience, I have added a manual pump with an airtank attached to the pneumatic system, to be used in need of a high pressure. It was in fact unnecessary, as the pneumatics powered only the outriggers, which don’t require much pressure. There is also a PF XL motor that drives the winch inside the superstructure. My intent of using it to extend the boom failed due to the transmission between the motor and the boom being too weak. The boom was eventually extended manually by a crank. There is also a V4 piston engine in the superstructure, as the real Liebherr crane has a separate superstructure engine.

The crane has been a very aspiring project, perhaps too aspiring in face of the lack of linear actuators. Many solutions that worked well in smaller models were rendered useless here by the sheer size and weight of the vehicle. It has, however, been a precious experience, that taught me a lot about the limitations implied by the huge size of a model. One year later, it still remains the biggest thing I’ve ever built.

Fantastisk build ! Now you defendly ned to build the liebherr 11200 9.1 too ! And make sure to make building instruktions for it that I can get/buy from you

Super cool I still don’t understand how you find room for all those things u put in it like suspension

@Abhishek

That’s because it’s not for sale and you won’t find it in any shop.

i want to buy i but unable to locate the store and price of the product.

i am from india.

@Mecho12345

http://www.bricklink.com/catalogList.asp?catType=M&catString=36

Hi serial

Where do you get techfigs, I cant find them On bricklink.

@cbhs I’m from dunedin nz, hope you didn’t lose to much in the earthquake

@Timo i like the actuators on your moc

@Sariel

yeah i see what you mean right now i havent even tested weather a motor will turn it all i have done is linked up 9 axles and turned it by hand but its very hard to turn also thanks for the advice i might add diffs although it will be extremly hard

@peter

Bevel gears and knobs generate pretty much the same friction. Perhaps it’s simply a heavy model. Perhaps the gear reduction is too small. It’s really hard to guess since I haven’t even seen how your model is built.

@Sariel

are bevel gears easyer to turn than 4 knob gears? and dose mutiple axles linked to 1 drive make it harder to drive

@Sariel

i have done that also im not using unversal joints instead im using bevel gears on the steering axles mybe i should use bevel gears instead of 4 knob gears?

@peter

When something is hard to turn, I usually add a gear reduction.

@Sariel

turning isnt the problem althouhg i do agree wiht you the problem is that the drive itself is extremly stiff and very hard to turn should i drvie less axles or change to bevels gears or do both im building in 1:25 scale

@peter

Peter, you do realize that differentials are what you need for turning? They exist to make turning possible and easy. If you remove them, it’s no wonder turning is very hard.

@Sariel

no im not but do you think that 9 axle drive is too much or is it just the type of gears im using

@peter

So you’re not using differentials at all?

hi again i am now making a liebherr ltm 11200 mobile crane in mammoet colours but i have hit a problem i have made all axles driven and 7 axles steered instead of 8 due to the spacing problem but my main problem is the drive is hard to turn; i am using 4 knob gears to direct the drive from going from front to back down the chassis to each wheel and i think they might be the problem can you help me with it and me an idea of how i am going to make it easyer? should i change the 4 knob gears to double bevel gears? thanks

the picture with the extendet crane arm looks so funny 😉

i have build an liebherr lg1750 with 16x4x12 but i failed by the superstucture

@cbhs

It did, and the motors are listen in the description. Try reading it.

Hi, had this had motorized drive and steering, how many XL motors would you have expected it’d have taken to do so? Thanks.

Hi, yes that link is exactly what I was after, thank you. Love your stuff! (all the way from Christchurch, New Zealand)

@cbhs

Like this? http://sariel.pl/2009/01/pf-handset-customized/

Hi, I notice on your remote, one of the sticks is modified so you can move a stick laterally for controlling the steering. It makes steering the vehicle on the remote more intuitive I take it. Would you consider making instructions/tutorial on how to do make this? Thanks

@Sariel

thanks

Read this Peter: http://www.eurobricks.com/forum/index.php?showtopic=41672&view=findpost&p=735016

where i said could you do a detailed picture i was talking about the liebher LTM 1200 thats on your future projects list. anyway could you help me in desgining a 3 section boom that will be lifted by actuatars or watever they are called because i cant work out how i am going to make it extend i know how to make a 2 section one using a worm cog or a gear but im builed a boom thats 3 section and is going to be exactly 92 cm long unextyended and about 150cm extended thanks.

in HQ please!

@peter

So… what do you know actually? Because it sounds like you want me to build the whole crane for you or something.

Could you please show a detailed picture of the crane arm when you finish it the one on your new crane because I would like to build a mobile crane myslf but i just cant think of how to build a working extending arm and how to add power functions to the arm and make it extend and carry large weights while being not too big. thankyou for looking at this comment peter.

oh ok then thankyou anyway

@peter

I don’t make instructions on a principle.

I would just like to say this is a great model and the size and the fact that it works blows me away. I would also like to ask do you know that you are making the Liebherr LTM 1200 I was wondering if you could make instructions for it.

@André

No, I don’t.

Hi.

Nice crane. Do you have the drawing for the boom?

wow! this is impossible!

@Raperrek

Because more than 90% of visitors isn’t Polish.

Nice polish plag men ;p

Why this site isn’t is in Polish ?!

Amazing!!! I’ve been mucking around building techno cranes since I was ten (I’m 22 now!) and you have built the most impressive one I’ve ever seen!

Nice model, mine is still in progress…