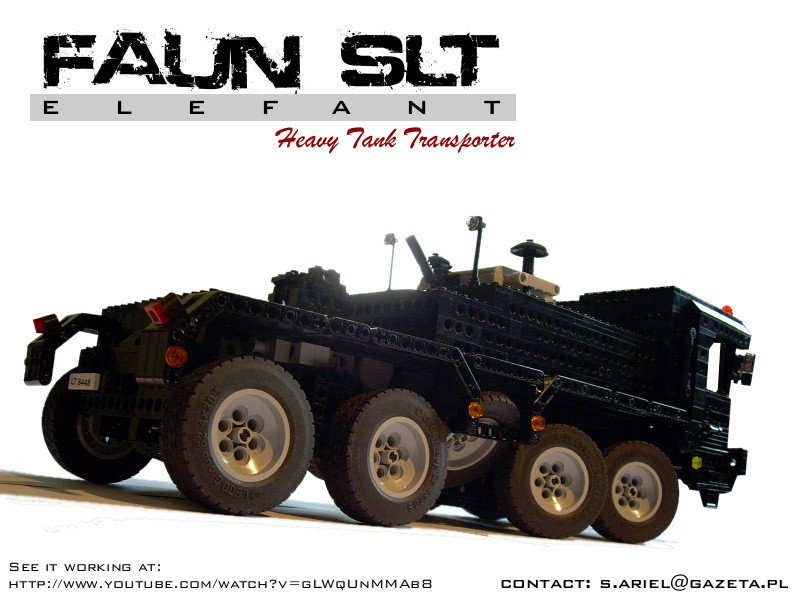

Faun SLT

Model of an 8×8 special truck designed to tow tanks. Features 8×8 drive, 4 wheels steering, full suspension, drivetrain with an adder, pneumatic carriage outriggers and remotely raised carriage ramp.

Datasheet:

Completion date: 24/03/2008

Power: electric (Power Functions) / pneumatic (fed from internal manual pump)

Dimensions: tractor – length 59 studs / width 20 studs / height 23 studs, carriage – length 109 studs / width 24 studs / height 23 studs

Weight: tractor – 2.1 kg, carriage – 1.2 kg

Suspension: full pendular without shock absorbers

Motors: 2 x PF XL, 2 x PF Medium

Pneumatics: one circuit with manual valve and internal manual pump in the carriage

There are two versions of the Faun SLT tank transporter: Elefant and Franziska. While externally almost identic, they are very different internally, with Franziska being a simplified, cheaper version with a limited off-road performance, and built from less specialized, more common parts. Both versions use different carriages, with different number of axles. What I’ve built is a 1:19 model of the Elefant version.

The look of the truck is fairly accurate, except for the cab, which is too tall by at least 2 studs. I have also sacrificed the details of gear located behing the cab, in order to gain space for the drivetrain.

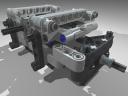

The drivetrain is quite space-consuming, as it consists of two PF XL motors connected by an adder. Normally, an adder sums up the speed and torque of two motors into a single output. Here, however, I have used a different gear ratio between the adder and each of the motors. This results in a different speed and torque the adder receives from every motor, which means that they can be combined to work like gears of a gearbox. All it takes is an independent control of each motor, and thus 4 combinations are possible: motor A alone, motor B alone, motor A minus motor B, and motor A plus motor B. Unfortunately, this theoretically great solution has one real disadvantage: if the adder’s output meets sufficient resistance, it stops and the motors start to drive each other instead. More precisely: the motor which is geared down more drives the other motor. It doesn’t cause any damage to the PF system, but it stops the vehicle entirely. Since the adder uses a differential, this situation can be supposedly prevented by using a differential lock. The locked adder would then work like a regular rigid axle, and transfer the drive to the output like it should, provided on of the motors is off & driven by the other (because of the gear ratio difference). I have not yet tried locking the adder under such circumstances.

The steering system includes axle 1 & 2, which have the same turning radius, just like in the real truck. Both are controlled by a PF Medium motor. I have used my compact pendular driven & steered suspension module again, with some additional reinforcement. It works well, but under extremely heavy low a single weak point fails: the 8-teeth gears. These can’t be replaced in this construction, and they are the weakest gears possible, even though preceded by a worm gear here. Both front axles have no shock absorbers, to save space. The vehicle is stable thanks to the axles 3 & 4, which are driven through a single differential, and suspended on longitudinal rocking levers. This is a very simple solution, which needs no shock absorbers neither.

The last motor, a second PF Medium, is located at the back of the truck and has an output that exits the hull in form of an universal joint in the middle of the carriage latch. Upon connecting to the carriage, the output drives a ramp raising mechanism in the carriage, through a long axle that reaches the carriage’s rear end, and a worm gear.

The carriage is pretty simple, fitted with 4 axles that use the same pendular solution as axles 3 & 4 in the truck: the longitudinal rocking levers. There is a very simple pneumatic system in the front part of the carriage, that deploys a pair of outriggers to support the carriage when disconnected from the tractor. Some of the photos show the carriage with the hull of the S Tank, which has been at the disassembly stage when the Faun was finished.

The model met with a very positive response, both local & worldwide. The use of worm gears, however, caused the vehicle to be very slow, which prompted me to cut and shorten the video, and some people believe it to be an attempt to put them on. I’ve been also disappointed by the problems with 8-teeth gears in the drivetrain, which rendered the truck unable to tow loads heavier than approx. 6 kilograms despite all the torque it had.

Photos:

Video:

Media reference:

YFOLe (Polish only), Young Spacers Association Blog

@ron

the SLT 50 –> “Elefant” has a V8-Engine, the “Elefant” with MSA (Modulare Schutzausstattung – modular protective equipment) has a V12-Engine

@Ev3fan

You should comment less and build more, I think.

The adder concept is really interesting. Sadly it doesn’t work:( .but Why don’t retry it with worm gears? This is an idea you should work on , I think.

@ron

For easier connecting. Seventh photo explains that.

Hi Sariel.

why does the trailer have suspension in the part where it hooks on to the truck? is it like that in the original?what is the purpose?

Cheers,

Ron

Thanks a lot, will try it out, you’re great to reply so quick!

@ron

Thanks. No, I don’t know the original engine, yes, the new 8t gears should do better, and no, the trailer had no steering.

Hi Sariel.

Good job! I just wanted to ask you something about this truck. Do you know what engine the real truck had? Cause I want to do this model and I believe i might have enough room for a fake engine.

Another point, why was it that the 8 tooth gears failed? I know that they do create a lot of backlash but did you ruin some of them? Also, do you think the new version of these small gears would work better?

Finally, does the trailer have steering? Some do….

Thanks in advance and waiting for your next masterpiece!!

Ron

@lave

No.

Hello you could send me the instructions of the faun slt thank you anticipate

@Sariel

I should say the inspiration was making the PF remote intuitive without adding stuff to it.

@Sariel

That’s true. But as I said, it would be an interesting experiment in mechanics. Maybe I should borrow my friend’s PF system and try it out. 🙂

P.S. the second idea could supply return-to-centre functionality.

@bachaddict

If you want to make a car intuitive to use with a PF remote, it’s way easier to build a steering wheel on a remote.

As an interesting thought experiment, I have considered different ways of controlling a car with rack-and-pinion steering like a skid-steered vehicle. The ideas I had:

1. Two motors drive the rear wheels through an adder, but are also connected to a subtractor that controls the steering. Thus the steering system is activated when the motors turn in different directions or only one is turned on.

2. As above, two motors are connected with an adder. This time, each motor controls a lever through a clutch gear, such that a motor can push the steering in one direction when the other motor does not provide a balanced resistance.

Do you understand? This is to make a car intuitive to use with a PF remote.

niezły pojazd… naprawdę warty podziwu, ciekawe wykonanie, tylko jedna rzecz mi się nie zbyt podoba………… mianowicie mała prędkość =)

@Jetro

The same, just like in the original truck.

how do the two front axles work?

Do the move the same or different?:)

@kama12811

Właściwie to ma kolebki. A poza tym jest raczej stary.

ale super pojazd!widze że ma nie zależne zawieszenie,nawet koło zapasowe wszystkie szczegóły bardzo mi się podoba